Electronics Enclosure Design: A Practical Guide

Your agency just landed a huge campaign, and the core idea involves a custom piece of tech—a smart device for an influencer kit or an interactive object for an experiential event. The concept is brilliant, but now you have to actually build it. This is where the creative vision meets the laws of physics. The critical, and often overlooked, bridge between your idea and a functional product is its physical shell. A thoughtful electronics enclosure design does more than just protect the components inside; it defines the user experience, communicates brand quality, and ensures the final product is durable, intuitive, and ready for the real world.

Key Takeaways

Treat the Enclosure as the Core User Experience: More than just a protective case, the enclosure is the primary physical touchpoint that communicates your brand’s quality and thoughtfulness through its material, form, and feel.

Integrate Engineering with Creative from the Start: A successful product merges aesthetics with practical needs like heat management, durability, and EMI shielding. Addressing these technical requirements early prevents late-stage compromises to your vision.

Plan for Production Before Finalizing the Design: To ensure a smooth launch, your design must be manufacturable. Prioritizing Design for Manufacturing (DFM) principles saves time and money by making assembly efficient and quality consistent.

What is an Electronics Enclosure?

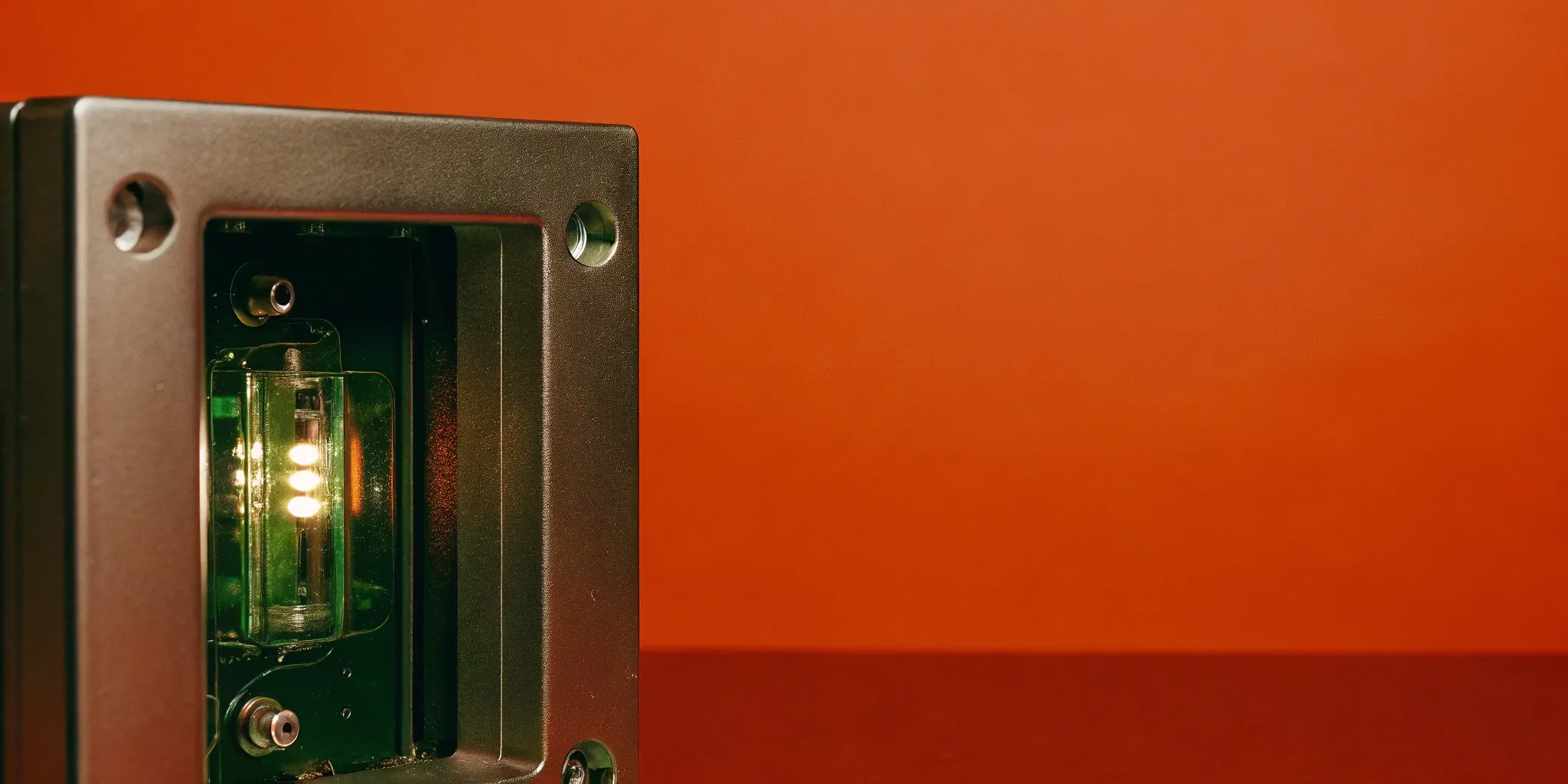

Think of an electronics enclosure as the custom-fit armor for your product's internal components. It’s the protective shell that turns a raw circuit board and a tangle of wires into a finished product that a customer can hold, use, and trust. But it’s so much more than just a box. A well-designed enclosure is where your brand’s physical identity comes to life. It dictates how the product looks, feels, and stands up to real-world use.

For creative agencies venturing into physical products, the enclosure is the primary touchpoint for the user experience. It’s the first impression and the lasting one. A great enclosure provides physical strength, protects the sensitive electronics from the outside world, and creates an intuitive interaction for the user. Whether you’re developing a high-tech device for an immersive campaign or a piece of branded merchandise, the enclosure is the bridge between your creative concept and a functional, market-ready product. Getting it right means balancing aesthetics, engineering, and manufacturability from day one.

Its Core Job: Protection and Performance

At its most basic level, an enclosure’s job is to keep the sensitive electronics inside safe. This means protecting the components from physical impacts, dust, moisture, and other environmental threats. The outer shell is the first line of defense, ensuring that a drop, a spill, or a bumpy ride doesn’t spell the end for the device. A thoughtfully designed PCB enclosure also helps with performance by managing heat and shielding the internal parts from electronic interference that could cause glitches.

But protection is only half the story. The enclosure is also responsible for the product's look, feel, and usability. It’s what makes a device feel premium and intuitive, or cheap and clunky. For any branded product, this is critical. The materials, finish, button placement, and overall form factor all contribute to the user’s perception of your brand and the quality of the experience you’re delivering.

Meeting Industry Standards

Beyond looking good and feeling solid, every electronics enclosure has to follow important safety rules and regulations. These aren't optional suggestions; they are mandatory requirements that ensure your product is safe for users and legally compliant for sale in different markets. Depending on your product and where it will be sold, you’ll need to meet standards like UL (Underwriters Laboratories) in North America or CE (Conformité Européenne) in Europe.

To make this easier, organizations have created classification systems to help you choose the right level of protection. The National Electrical Manufacturers Association (NEMA) provides standards that define how well an enclosure protects against environmental hazards like water, dust, and corrosive agents. An enclosure with a NEMA 4 rating, for example, is built to be watertight. Understanding these standards early in the design process is key to avoiding costly redesigns and delays down the road.

How Enclosures Impact Your Product

The design of an enclosure has a ripple effect across the entire product. It’s not just a shell—it’s an integral system that influences everything from performance and reliability to cost and user satisfaction. A poorly designed enclosure can cause a device to overheat, making it unreliable or even dangerous. It can fail to block electromagnetic interference (EMI), leading to spotty performance. And if it’s difficult to assemble, it can drive up manufacturing costs and introduce quality control issues.

Ultimately, designing an electronic enclosure is a complex balancing act. It requires a deep understanding of materials, manufacturing processes, thermal dynamics, and user-centered design. Every decision, from the type of plastic used to the placement of a vent, impacts the final product. This is why a strategic approach is so important—it ensures the final product is not only beautiful and on-brand but also safe, reliable, and ready for the real world.

Key Design Decisions to Make

Designing an electronics enclosure is much more than just creating a box to hold your components. It’s a series of strategic decisions that directly impact your product's performance, durability, and the overall user experience. Getting these foundational choices right from the start saves you from costly redesigns and production headaches down the line. For creative agencies, these technical details are what make a brilliant concept a functional, real-world product that people can actually use and love.

Think of the enclosure as the bridge between your creative vision and the engineered reality. It’s where form meets function. Every choice—from the material you select to the way you manage internal heat—shapes how the final product looks, feels, and operates. A sleek, minimalist design is fantastic, but it also needs to protect the sensitive electronics inside from a clumsy drop, a spilled coffee, or a humid day. By thinking through these key factors early in the process, you ensure the final product is not only beautiful and on-brand but also reliable and built to last. This is where we translate your big idea into a tangible, manufacturable, and market-ready asset.

Plan for Environmental Factors

First things first: where will your product live? The answer dictates its entire physical design. An enclosure destined for a climate-controlled office has very different needs than one built for an outdoor installation or a busy factory floor. You need to plan for every potential challenge, including dust, moisture, chemicals, and weather conditions like UV rays or ice. The industry uses a standardized IP Rating system to classify the level of protection an enclosure offers against solids and liquids. Choosing the right rating ensures your electronics stay safe and functional, no matter what the environment throws at them.

Choose the Right Materials

Your material choice is directly tied to the environmental factors you just identified. For indoor products, plastics like polycarbonate or ABS are often a great fit—they’re lightweight, versatile, and cost-effective. But if your product is heading outdoors or into a demanding industrial setting, you’ll likely need the strength and durability of metals like aluminum or stainless steel. The material also plays a huge role in the product’s aesthetic and tactile feel, which is critical for creating a memorable brand experience. It’s a balance of durability, appearance, and budget that we can help you define.

Define the Size and Shape

Figuring out the enclosure's dimensions is a careful balancing act. It needs to be compact enough to be practical and user-friendly, yet spacious enough to house all the internal components—the circuit board, battery, connectors, and wiring—without cramming them in. The overall shape, or form factor, is where industrial design and mechanical engineering truly intersect. It’s not just about creating something that looks good; the shape influences everything from how a user holds the device to how easily it can be assembled on a production line.

Manage Heat and Airflow

Electronics generate heat, and too much of it can degrade performance and shorten a product’s lifespan. That’s why effective thermal management is non-negotiable. Depending on how much heat the components produce, your enclosure might need passive cooling solutions like vents and heat sinks, which dissipate heat into the surrounding air. For more powerful devices, active cooling with fans might be necessary. A well-engineered design ensures there’s a clear path for air to flow, keeping everything running smoothly and reliably.

Shield Against Interference

In our wirelessly connected world, your device needs protection from invisible signals that can disrupt its function. This "noise" is known as electromagnetic interference (EMI) and radio-frequency interference (RFI). Without proper shielding, your product could malfunction or interfere with other nearby devices. This is especially critical for products with wireless capabilities or sensitive sensors. Using conductive materials like aluminum or steel for the enclosure is an effective way to create a shield, ensuring your product works as intended and can pass regulatory certification.

A Guide to Enclosure Materials

Choosing the right material for your product’s enclosure is one of the most important decisions you’ll make. It defines the product's look, feel, durability, and cost. Think of it as the handshake of your product—it makes the first impression. Whether you need something rugged and industrial or sleek and modern, the material sets the tone. It’s a decision that blends creative vision with practical engineering, and our job is to help you find the perfect match for your project's goals and budget.

Working with Metal

Metal enclosures give a product a premium, durable feel that’s hard to beat. They’re perfect for high-end consumer electronics, branded merchandise that needs to last, or any project where strength is a top priority. Aluminum is a popular choice because it’s lightweight, resists corrosion, and has a clean, modern aesthetic. For projects needing more muscle, stainless steel is incredibly strong and naturally rust-proof. If budget is a key driver, options like cold-rolled steel offer great strength at a lower cost, though they’ll need a protective coating to keep them looking sharp. We can guide you through the finishing options to match your brand’s exact look.

The Benefits of Plastic and Composites

When you need design flexibility, plastics and composites are your best friends. These materials can be molded into complex, organic shapes that would be difficult or expensive to create with metal. This makes them ideal for ergonomic products, unique campaign assets, or enclosures with intricate details. Common choices like ABS are great all-around performers, while polycarbonate (PC) offers superior impact resistance and can even be made transparent to show off the tech inside. For products that need to withstand heat or weather, specialized blends give you the best of both worlds. The versatility of injection molding allows for a huge range of colors, textures, and finishes, giving you complete creative control.

Exploring Sustainable Options

More and more brands are making sustainability a core part of their story, and your product’s materials are a tangible way to show that commitment. The world of sustainable materials is full of exciting innovations, from recycled plastics and ocean-bound composites to plant-based bioplastics. These options can reduce a product's environmental footprint without compromising on performance or aesthetics. Choosing a sustainable material can be a powerful part of your campaign's narrative, resonating with environmentally-conscious consumers. We’re always exploring new material technologies and can help you find an option that aligns with your brand’s values and connects with your audience.

Balancing Cost and Performance

Ultimately, the best material is the one that meets your performance requirements, creative vision, and budget. It’s always a balancing act. A beautiful, custom-milled aluminum enclosure might be perfect for a luxury product, but a cleverly designed ABS plastic housing could deliver a similar user experience for a fraction of the cost. Part of our process is exploring these trade-offs with you. We apply Design for Manufacturing (DFM) principles to ensure your concept is achievable within your budget. Sometimes, a small tweak to the design or a different material choice can lead to significant savings without sacrificing the core idea. We’ll help you make informed decisions to get the best possible product to market.

Advanced Features to Consider

Once you’ve nailed down the basics, you can start thinking about features that take your product from functional to exceptional. These advanced considerations are what separate a good enclosure from a great one, ensuring your product not only works flawlessly but can also handle real-world challenges. For agencies, getting these details right can be the difference between a campaign asset that wows and one that fails under pressure. Let’s look at a few key areas where a little extra planning goes a long way.

Smart Thermal Management

High-performance electronics generate heat, and if that heat has nowhere to go, it can cause slowdowns, malfunctions, or even permanent damage. Smart thermal management is all about designing a way for your product to stay cool. This can be as simple as adding vents for airflow or as complex as integrating fans and heat sinks—special components that draw heat away from sensitive chips. The material you choose plays a big role, too. An aluminum enclosure, for example, can act as a giant heat sink, naturally dissipating warmth while also looking sleek and premium. Thinking about thermal design early ensures your product remains reliable and performs at its peak.

Effective EMI/RFI Shielding

Ever notice your speakers buzzing when your phone is too close? That’s a mild form of electronic interference. Electromagnetic interference (EMI) and radio-frequency interference (RFI) are invisible waves of energy that can disrupt how a device works. Shielding protects the sensitive components inside your enclosure from this "electronic noise." Metal enclosures, like aluminum or steel, are naturally great at this. If you’re using plastic, special conductive coatings can be applied to get the job done. Just remember that this shielding can also block intentional signals, like Wi-Fi or Bluetooth. We can design around this with strategic cut-outs or external antennas so your product stays connected.

Sealing for Harsh Environments

If your product is meant to be used outdoors or in a demanding setting, you need to protect it from the elements. Dust, moisture, and chemicals can easily find their way inside an unsealed enclosure and wreak havoc on the electronics within. This is where environmental sealing comes in. Using gaskets, seals, and specific construction techniques, we can make an enclosure water-resistant or even fully waterproof. The level of protection is standardized by an IP rating (Ingress Protection), which clearly defines how well the enclosure can stand up to dust and water. This is crucial for creating durable, long-lasting products that can handle any environment they’re thrown into.

Integrating Smart Technology

The enclosure doesn’t have to be just a passive box. With today’s technology, the packaging itself can become part of the product’s function. We’re seeing incredible innovation in smart materials and integrated tech that can make a product more interactive and user-friendly. Imagine an enclosure that changes color based on temperature, incorporates touch-sensitive controls directly into its surface, or uses embedded lighting to guide a user. By thinking beyond a simple container, you can create a more cohesive and memorable experience. This is where industrial design and engineering really come together to build something that feels truly futuristic and elevates the entire product.

Design with Manufacturing in Mind

A brilliant enclosure design is only as good as your ability to produce it. This is where a lot of great ideas hit a wall. Designing with manufacturing in mind from day one is the single most important step to ensure your product launch is smooth, on-budget, and successful. This approach, known as Design for Manufacturing (DFM), is all about creating a product that is not only beautiful and functional but also efficient and cost-effective to produce at scale.

Think of it as building a bridge between the creative concept and the physical reality. By considering the manufacturing process during the design phase, we can anticipate and solve potential problems before they become expensive, time-consuming headaches. This means making smart choices about materials, structure, and assembly that streamline production, reduce waste, and ensure consistent quality. For your agency and your client, this proactive approach minimizes risk and maximizes the chances of launching a product that performs flawlessly and looks exactly as you envisioned. It’s how we turn an ambitious idea into a tangible, market-ready reality without the drama.

Key DFM Principles

At its core, DFM is a set of practical guidelines that ensures a design is optimized for its specific manufacturing process. For example, if your enclosure will be made using injection molding, we’ll focus on details like maintaining a uniform wall thickness to prevent cosmetic defects and structural weaknesses. We also prioritize simplifying the design by reducing the number of individual parts, which lowers tooling costs and simplifies assembly. By following these established DFM principles, we create a product that is inherently easier and more reliable to build, ensuring the final quality lives up to your creative vision.

Streamline the Assembly Process

How an enclosure is put together has a huge impact on production time and cost. A design that’s difficult to assemble can lead to errors, delays, and higher labor expenses. We focus on creating features that make assembly intuitive and efficient. For instance, adding subtle elements like rounded corners, edges, ribs, and gussets not only makes the enclosure stronger but also helps guide parts into place. We also design clever snap-fits to reduce the need for screws and adhesives, which speeds up the entire process. These small, intentional details add up to a product that can be assembled quickly and correctly every time.

Plan for Quality Control

Quality isn't something you inspect for at the end; it's something you build in from the beginning. We integrate quality control measures directly into the design phase to catch potential issues before a single part is ever made. By using precise 3D models for fit verification, we can digitally assemble the entire product to check for interferences and ensure all components have the proper clearance. This virtual prototyping allows us to refine tolerances and confirm that everything will fit together perfectly on the assembly line. This proactive approach significantly reduces the risk of defects and improves the overall quality and consistency of the final product.

Ensure Your Design Can Scale

A successful launch is just the beginning. Your enclosure design needs to be ready for what comes next, whether that’s a larger production run or future product updates. We design enclosures with scalability in mind, which means we consider how the design can accommodate future modifications or increased production volumes without requiring a complete overhaul. This involves selecting materials and manufacturing processes that are efficient at both low and high volumes. Planning for scalability from the start ensures that as your product’s demand grows, your ability to scale production can grow right along with it, protecting your investment for the long term.

Prioritize Safety and Accessibility

A product’s enclosure is more than just a protective shell; it’s the primary way a person interacts with the technology inside. If that interaction is confusing, difficult, or feels unsafe, the entire brand experience suffers. Great design anticipates user needs, making the product not only functional but also intuitive and easy to handle. For agencies creating branded products or campaign assets, this is where the creative vision meets real-world usability. A sleek, beautiful object that’s impossible to use is a missed opportunity. That's why we treat safety and accessibility as core design pillars, not just checkboxes.

Thinking about these elements from the start protects both the user and the brand. It ensures the final product is not just visually compelling, but also responsible and user-friendly. This means planning for how someone will plug it in, turn it on, and even perform basic maintenance without frustration. A well-designed enclosure guides the user effortlessly, making the technology feel approachable and reliable. When you're launching an influencer package or a piece of high-end merchandise, that seamless first experience is everything. It’s the difference between a product that gets used and loved, and one that gets put back in the box.

Create Easy Access for Components

Every physical touchpoint on your product is a chance to make a good impression. Clear, well-placed buttons, ports, and screens are fundamental to a positive user experience. When designing an enclosure, we map out where these interactive elements should go to feel natural and intuitive. This includes adding clear labels or icons and ensuring that access panels for things like SIM cards or memory cards are easy to open without special tools. Internally, a clean layout is just as important. Thoughtful cable management prevents internal components from getting damaged during shipping or use, which is crucial for influencer kits and promotional products that need to work perfectly right out of the box. A well-organized interior also simplifies any potential troubleshooting, ensuring the product remains functional and impressive long after the unboxing.

Simplify Future Maintenance

Even the most robust products may eventually need a battery change or a simple repair. Planning for this from day one shows a commitment to quality and longevity. A design that simplifies maintenance is one that respects the user’s time and investment. This means thinking about how the enclosure will be opened and ensuring there’s enough space inside for fingers and tools to access key components. For example, if your product includes a replaceable battery, the access door should be obvious and easy to operate. No one wants to hunt for a microscopic screw or pry open a case that feels like it’s going to break. By designing for easy serviceability, you create a product that feels less disposable and more valuable, reinforcing the premium quality of the brand you’re representing.

Integrate Essential Safety Features

Safety is non-negotiable in product design. It builds trust and protects the user, the product, and the brand’s reputation. This starts with adhering to recognized industry standards, which certify that a product has been tested for safety. Integrating features like secure locks, tamper-evident seals, or even emergency shut-off buttons adds another layer of security, depending on the product’s function. Beyond certifications, physical design plays a huge role in safety. This includes using non-toxic materials, designing with rounded edges to prevent injuries, and ensuring the enclosure properly insulates all electrical components. Clear safety warnings and instructions should also be integrated seamlessly into the design, providing essential information without cluttering the aesthetic.

Design an Intuitive User Interface

The enclosure is the physical manifestation of the user interface. It’s what people see, touch, and hold, and it’s responsible for translating complex technology into a simple, enjoyable experience. A great enclosure doesn’t just hide the circuit boards; it makes the device approachable and easy to handle. The form, weight, texture, and balance all contribute to how the product feels in a user’s hands. An intuitive UI guides the user naturally. For instance, a subtle indentation can show where to press, or a textured surface can indicate a grip point. The placement and feel of buttons should provide clear tactile feedback, confirming an action has been completed. By merging thoughtful ergonomics with your brand’s aesthetic, we create a product that not only looks incredible but feels like it was designed just for the user.

What's Next in Enclosure Design?

The world of product design doesn’t stand still, and enclosures are no exception. As technology gets smaller, smarter, and more integrated into our lives, the boxes that house them have to keep up. For agencies and brands looking to create physical products that feel fresh and innovative, understanding these trends is key. It’s not just about aesthetics; it’s about building products that are flexible, connected, and responsible. Staying ahead of these shifts ensures that the product you’re developing for a campaign or launch feels current and is built to last, both functionally and conceptually. From modular systems that offer incredible flexibility to sustainable materials that tell a better brand story, the future of enclosure design is full of exciting possibilities.

The Rise of Modular Enclosures

Think of modular enclosures as a high-end set of building blocks. Instead of designing a completely new enclosure for every product variation, a modular approach uses a system of standardized, interchangeable parts. This creates a framework that can be easily adapted for different sizes, components, or features. For agencies working on tight deadlines, this is a game-changer. It allows for rapid prototyping and customization without starting from scratch every time. This growing demand for customization and modularity means you can create unique enclosures for different campaign activations or product tiers while reducing development time and costs, giving you the flexibility to meet diverse client needs quickly.

Designing for IoT and Connectivity

As more products become part of the Internet of Things (IoT), enclosure design faces a new set of challenges. These devices need to be compact and durable while seamlessly communicating with the outside world. This means the enclosure must protect sensitive electronics without blocking Wi-Fi, Bluetooth, or cellular signals. It’s a delicate balancing act. Engineers have to manage heat dissipation in a tiny space, ensure signal integrity for antennas, and still create a product that can withstand daily use. For agencies, this opens the door to creating smart, connected merchandise or interactive campaign assets that bring a brand’s digital presence into the physical world, all made possible by thoughtful electronic packaging technology.

Adopting Sustainable Practices

Sustainability is no longer a niche request; it’s a core expectation for modern brands and consumers. This shift is heavily influencing enclosure design, pushing teams to prioritize eco-friendly materials and circular design principles. This can mean using recycled or bio-based plastics, designing for easy disassembly and repair, or choosing materials that can be efficiently recycled at the end of the product’s life. The push toward more sustainable practices in enclosure design isn't just about meeting regulations—it's a powerful storytelling tool. For an agency, proposing a product built with sustainable principles can strengthen a client’s brand identity and resonate deeply with an audience that values environmental responsibility.

A Look at Future Technologies

The cutting edge of enclosure design is being shaped by breakthroughs in both materials science and manufacturing. We’re seeing the development of advanced composites that are lighter and stronger than traditional plastics, as well as smart materials with properties like self-healing or embedded conductivity. At the same time, new manufacturing processes are making complex geometries and integrated features more accessible than ever. These innovations in materials and manufacturing are what allow us to build the next generation of electronics. For creative agencies, this means the gap between a wild concept and a manufacturable product is getting smaller, opening up new avenues for creating truly groundbreaking physical experiences.

Your Enclosure Design Checklist

A great idea is one thing, but a great product requires a plan. This checklist will help you cover your bases and ensure your enclosure design is thoughtful, functional, and ready for the real world. Think of it as your guide to asking the right questions from the start, turning your creative vision into a tangible product that works exactly as it should.

Outline Your Project Plan

Before any design work begins, you need a clear project plan. This is where you define the what, where, and how of your product. Start by thinking about the environment—will it be used indoors, outdoors, or in a factory setting? This decision influences everything from material selection to sealing. You’ll also need to consider thermal management for heat-sensitive components, accessibility for assembly and maintenance, and overall durability. A well-defined product requirements document acts as your North Star, keeping your creative goals and technical needs perfectly aligned throughout the development process.

Know Your Testing Requirements

How will you know if your design is a success? By defining your testing requirements upfront. These are the specific, measurable standards your enclosure must meet to be considered complete. For example, does it need to survive a drop from a certain height? Does it need to be water-resistant? This is where standards like IP ratings (Ingress Protection) come into play, giving you a clear benchmark for protection against dust and liquids. Deciding on these requirements early on prevents costly redesigns and ensures the final product is robust enough for its intended use.

Validate Product Performance

A successful enclosure does more than just protect the electronics inside; it enhances the entire product experience. Performance validation is about confirming that the enclosure is doing its job effectively. Does it dissipate heat properly to keep the electronics from overheating? Does it feel solid and high-quality in a user's hands? Is it intuitive to open or operate? The enclosure is often the first thing a customer interacts with, making it a critical touchpoint for your brand. It’s the shell that delivers on the promise of the technology within.

How to Avoid Common Pitfalls

We’ve seen a few common missteps that can derail an enclosure project. First is the classic trap of designing a perfectly sealed fortress that no one can get into for assembly or repairs. Always balance protection with accessibility. Second is forgetting that electronics generate heat. Without a plan for ventilation—using features like vents, fans, or heat sinks—you risk performance issues and component failure. Thinking through these practical challenges early saves you major headaches down the road and leads to a much more reliable product.

Related Articles

Medical Device Design: The Complete 2025 Guide — Jackson Hedden

The Agency Guide to Outsourced Engineering and Design — Jackson Hedden

10 Best Industrial Design Agencies for Product Innovation — Jackson Hedden

Frequently Asked Questions

My agency has a creative concept for a product. Where do we even start with the enclosure design? The best place to start is by thinking about the user and their environment. Before we get into materials or mechanics, we need to answer a few key questions: Who is this product for? Where will they use it? What should it feel like in their hands? Defining the core user experience and the functional requirements first gives us a clear roadmap for all the technical decisions that follow, ensuring the final design is perfectly aligned with your creative vision.

How do we choose between using plastic or metal for our product? This decision really comes down to balancing your brand's aesthetic, the product's function, and your budget. Metals like aluminum give a product a premium, durable feel that’s great for high-end goods. Plastics, on the other hand, offer incredible design flexibility, allowing for complex shapes and a wide range of colors and textures at a more accessible cost. We can walk you through the trade-offs to find the material that best tells your product's story.

What is "Design for Manufacturing" (DFM) and why is it so important? Think of DFM as planning for production from day one. It’s the process of designing a product in a way that makes it efficient and reliable to build at scale. By considering the realities of the factory floor during the creative phase, we can avoid common pitfalls that cause delays and drive up costs. It’s what ensures your brilliant concept can be turned into a real, high-quality product without expensive surprises down the line.

Our product needs to be used outdoors. How do you make sure it can handle the elements? Protecting electronics from the environment is all about creating a solid defense. This involves selecting durable, weather-resistant materials and engineering a sealed enclosure using gaskets to keep out water and dust. We use a standardized IP rating system to define exactly how much protection is needed, so whether your product needs to survive a rainstorm or just a dusty warehouse, we can build it to last.

How can the enclosure design make our product feel more intuitive and user-friendly? The enclosure is the physical bridge between the user and the technology inside. We make that connection feel effortless by focusing on ergonomics and thoughtful details. This includes everything from the product's shape and weight to the texture of its surface and the satisfying click of a button. By carefully considering how someone will hold, carry, and interact with the device, we can create a product that feels natural and easy to use right out of the box.