What Are Industrial Design Services? A Simple Guide

In a competitive pitch, your agency is always looking for an edge—a way to deliver something the client wasn't expecting. Imagine being able to confidently propose a campaign that includes a custom-designed smart device or a completely unique piece of packaging. This is the power of having a product development partner in your back pocket. Think of industrial design services as your secret weapon, an extension of your own creative team that handles all the technical complexities of bringing physical products to life. It allows you to expand your agency’s offerings and execute more ambitious, immersive campaigns without the overhead of a full-time engineering department.

Key Takeaways

Design is a Strategy, Not Just a Look: Industrial design is where your creative vision meets real-world engineering. It ensures the final product is not only beautiful but also functional, manufacturable, and aligned with your client's business goals, protecting the project from costly surprises.

Find a Partner Who Speaks Both Creative and Engineering: Look for an integrated firm that handles both design and engineering in-house. This dual expertise is key to translating ambitious concepts into tangible products efficiently, preventing technical issues that can derail timelines and budgets.

Involve Your Design Firm from Day One: Bring your industrial design partner into the creative process early, even before the concept is fully finalized. This allows them to provide crucial feedback on feasibility and cost, helping you shape a stronger, more practical idea that's set up for a smooth production run.

What Are Industrial Design Services?

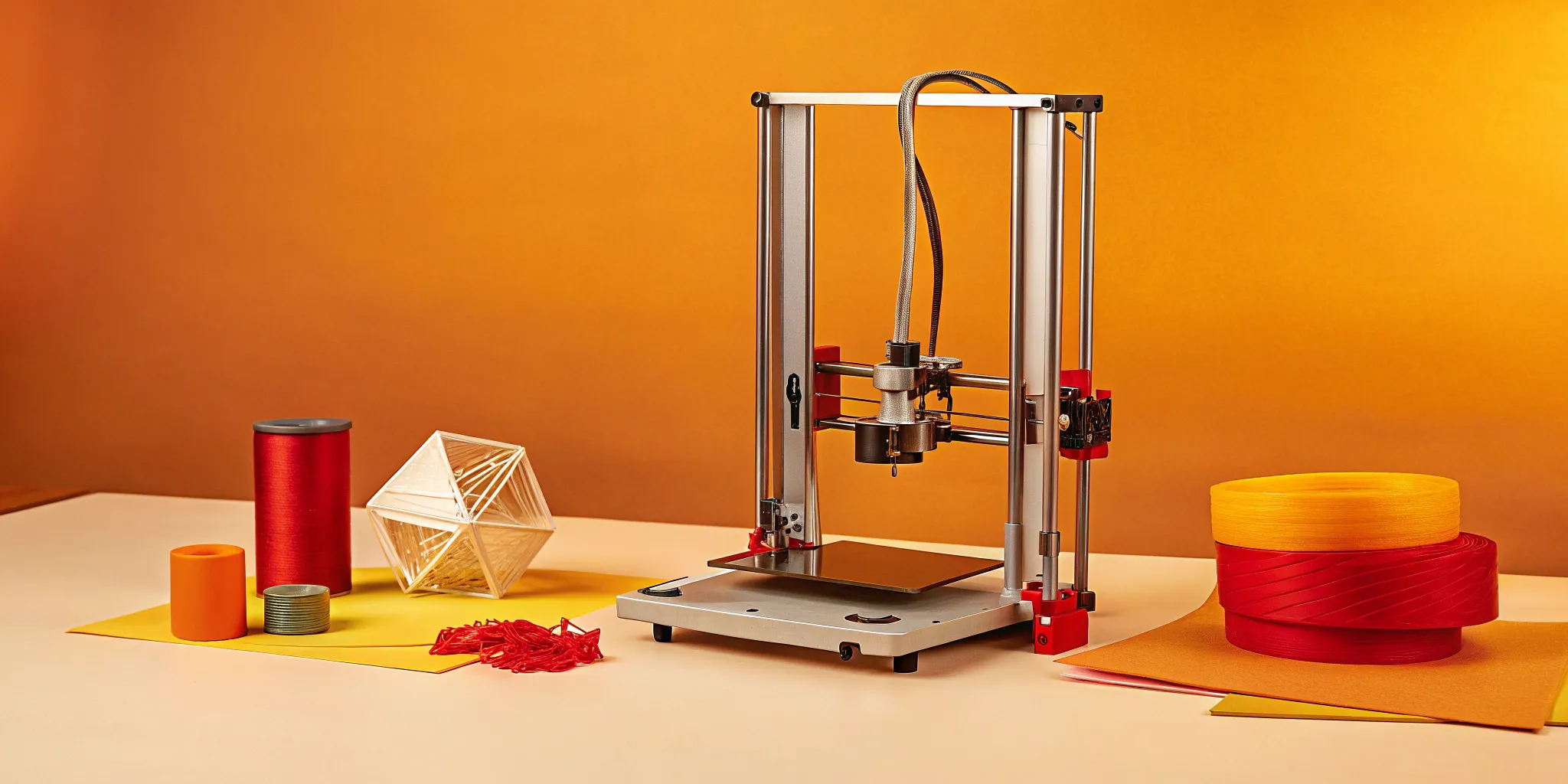

At its core, industrial design is the professional service of creating and developing products that are optimized for function, value, and appearance. Think of it as the bridge between a great idea and a real, tangible object that people can hold and use. It’s a discipline that blends art, science, and strategy to design everything from the smartphone in your pocket to the chair you’re sitting in. For creative agencies, this is the process that turns a brilliant campaign concept for a physical product into something that can actually be manufactured and put into the hands of your audience.

Industrial design isn't just about making things look good, though aesthetics are a huge part of it. A great industrial designer considers the entire user experience—how someone will interact with the product, how it feels, how it works, and how it aligns with the brand's story. By integrating this thinking early in the development process, you can create products that are not only beautiful but also intuitive, effective, and manufacturable. It’s a strategic approach that ensures your physical campaign assets, branded merchandise, or influencer kits are memorable for all the right reasons. It's what separates a generic piece of swag from a thoughtfully designed brand artifact that people will actually want to keep and use.

How the Industrial Design Process Works

The journey from a concept to a finished product is a structured one. It’s not about waiting for a single flash of inspiration, but about a methodical process of exploration and refinement. It generally starts with research to understand the user, the market, and the project's goals. From there, designers move into ideation, sketching out a wide range of concepts to explore different visual and functional directions. This is where the creative vision starts to take shape.

Once a promising direction is chosen, the real detailing begins. Designers use specialized software to create detailed 3D computer models, or CAD models, which define every curve, surface, and component. This digital blueprint is then used to create physical prototypes. Prototyping is a critical step that allows the team to test the product’s ergonomics, function, and assembly before committing to expensive manufacturing tooling. It’s an iterative cycle of designing, testing, and refining until the product is just right.

What Kinds of Projects Need Industrial Design?

You might be surprised by how many different projects benefit from industrial design. It’s a versatile field that touches almost every industry. For agencies, this is where you can really get creative and extend your campaigns into the physical world. Instead of just putting a logo on a generic item, you can create something truly custom and unforgettable.

Common projects include designing unique branded products, like high-tech gadgets or premium lifestyle goods that reflect a client’s brand identity. It’s also essential for creating custom packaging for influencer kits or product launches, where the unboxing experience is part of the story. Industrial designers also develop physical assets for experiential marketing activations, retail displays, and pop-up events. Essentially, if you can dream up a physical object that needs to look great, function flawlessly, and connect with an audience, an industrial design team can help you bring it to life.

How Industrial Design Transforms Product Development

Industrial design is the bridge between a creative idea and a real-world product. It’s a strategic discipline that shapes not just how a product looks, but how it works, how it feels, and how it’s made. For creative agencies, understanding this process is key to turning ambitious campaign concepts into tangible, successful products that clients and their customers will love. It’s about making sure the final product is desirable, feasible, and viable, hitting the mark on every level. This thoughtful approach ensures the physical assets you create for a campaign are just as compelling as the creative itself.

More than just aesthetics, industrial design is a problem-solving process that balances user needs with technical constraints and business goals. When you partner with an industrial design firm, you're not just getting a stylist; you're getting a strategic partner who can translate a brand's essence into a physical form while ensuring it can be produced on time and on budget. This integration of creativity and practicality is what transforms a good idea into a great product. It’s the difference between a cool-looking render and a physical product that functions flawlessly, feels great in the hand, and can be manufactured at scale. By thinking through every detail—from the first sketch to the final production line—industrial design de-risks the development process and sets your project up for success.

Create a Better User Experience

A product's success often hinges on how it makes people feel. Industrial design puts the user at the center of the process. We think about everything: How will someone hold this? What’s the first thing they’ll try to do with it? Is it intuitive or confusing? By focusing on these human factors, we design products that are not just functional but genuinely enjoyable to use. This deep empathy for the end-user ensures the final product truly resonates with its intended audience. For your client, this translates into stronger brand loyalty and a product that people actually want to keep and use, long after the campaign ends.

Stand Out with Strategic Aesthetics

In a crowded market, looks matter. But strategic aesthetics are about more than just a pretty shell. The form, color, material, and finish of a product all work together to tell a story and communicate your client’s brand identity. A well-designed product feels like a natural extension of the brand it represents. It creates an immediate emotional connection and makes a product feel premium and trustworthy. This is how you create something that doesn't just blend in but becomes a memorable part of the brand experience. Investing in high-quality industrial design is how you create products that stand out in the market and capture attention for all the right reasons.

Design for Manufacturing and Cost-Efficiency

A brilliant concept is only as good as its execution. This is where industrial design meets engineering. From the earliest sketches, we’re thinking about how a product will actually be built. This is called Design for Manufacturing (DFM), and it’s a critical step. We consider the right materials, the most efficient production methods, and how to simplify assembly to keep costs in check without sacrificing quality. This foresight prevents costly surprises and delays down the line. By integrating manufacturing logic into the creative process, we ensure your innovative idea is not only beautiful and functional but also commercially viable. This approach leads to efficient design and manufacturing processes that respect your client's budget and timeline.

What to Expect From a Professional Industrial Design Firm

Partnering with an industrial design firm is a structured, collaborative process that turns your agency’s creative vision into a tangible product. It’s about more than just aesthetics; it’s a strategic journey that blends art, science, and business to create something that looks incredible, functions flawlessly, and can actually be produced. A professional firm guides you through a proven workflow, ensuring every decision is intentional and aligned with your campaign goals. From initial brainstorming sessions to final manufacturing handoffs, the process is designed to be transparent and efficient. It all starts with a deep dive into your objectives and ends with a production-ready design that’s set up for success.

Starting with Research and Concepts

Before a single sketch is drawn, the process begins with research. A great design partner will dig into your creative brief, your client’s brand, the target audience, and the overall market landscape. By integrating industrial design into the early stages of product development, we can spot opportunities for innovation and ensure the final product truly connects with its intended users. This phase is all about exploration and alignment. We’ll develop mood boards, explore different visual directions, and present initial concepts. This collaborative discovery ensures we’re all on the same page and building on a strong strategic foundation before moving into more detailed design work.

Moving to Prototyping and Testing

Once a concept is chosen, it’s time to make it real. Prototyping is where ideas leave the screen and take physical form. This step is critical for identifying potential challenges early, from feasibility issues to user experience flaws that weren't obvious on paper. We create prototypes that you and your client can hold, use, and react to. This hands-on testing provides invaluable feedback for refining the product’s form, function, and feel. Whether it’s a simple visual model or a fully functional unit, prototyping allows us to iterate and improve the design, ensuring the final product is polished, practical, and ready for the real world.

Integrating Engineering and DFM

This is where design and engineering merge to prepare the product for production. Our team focuses heavily on Design for Manufacturing (DFM), which means we refine every detail to ensure the product can be made efficiently, affordably, and at a high level of quality. This involves creating precise 3D CAD models, selecting the right materials, and planning the assembly process. Successful collaboration between designers and engineers is key to transforming a beautiful concept into a manufacturable reality without compromise. We deliver a complete technical package that any factory can use to produce your product exactly as it was envisioned.

How to Choose the Right Industrial Design Partner

Finding the right industrial design partner is a lot like casting the perfect lead for a major campaign—the right fit makes all the difference. You’re not just looking for a firm that can make things look good; you need a true collaborator who can take a creative brief and turn it into a tangible, functional, and manufacturable product. Your partner should act as an extension of your own team, bringing the technical expertise that ensures your physical product is as compelling as your digital work.

When you’re vetting potential firms, it’s easy to get wowed by slick renderings. But a successful partnership goes much deeper. You need a team that understands the pace and demands of agency life and can bridge the gap between a brilliant creative concept and the physical realities of production. The best partners bring a strategic, engineering-led approach to the table, ensuring the final product works flawlessly, feels right in the user’s hands, and can actually be made on time and on budget. Focus on their technical skills, their past work, and how they manage their projects to find a team you can trust with your client’s brand.

Evaluate Their Experience and Technical Skills

First, look for a proven track record. You want a partner with deep experience in both industrial design and engineering. A team that only handles aesthetics will leave you scrambling to find an engineer to make it work, creating delays and communication breakdowns. Look for an integrated firm where designers and engineers work together from day one. This integrated approach is what keeps development efficient and ensures the final design is optimized for manufacturing. Ask about their technical capabilities—do they handle mechanical and electronic engineering in-house? The right partner has the skills to solve complex challenges and deliver a product that’s as technically sound as it is beautiful.

Assess Their Portfolio and Specialization

A portfolio is more than a gallery of finished products; it’s proof of a firm’s problem-solving ability. As you review their work, look for projects that align with your agency’s needs. Have they designed high-tech devices, custom packaging, or immersive brand assets before? Pay attention to the diversity and complexity of their projects. A strong portfolio should showcase not just the final result but the thinking behind it. Look for case studies that detail the journey from initial sketch to production-ready outcome. This gives you insight into their process and demonstrates their ability to translate a vision into a real-world product that meets specific goals.

Review Their Communication and Project Management Style

For an agency, this might be the most critical factor. Your industrial design partner needs to operate at the same speed you do. Clear, consistent communication is non-negotiable. During initial conversations, ask about their project management style. How will they keep you updated? Who will be your main point of contact? A nimble, execution-driven team is often a better fit for agency work than a large, bureaucratic firm. You need a partner who can integrate seamlessly into your workflow, respond quickly to feedback, and manage the technical details so you can focus on the client relationship. The goal is to find a team that feels like your own in-house product department, ready to execute on your creative brief with precision and expertise.

What Factors Influence the Cost of Industrial Design?

When you’re planning a budget for a client project, you need clear numbers. But when it comes to industrial design, the cost isn’t a simple line item. It’s a dynamic figure that depends entirely on what you’re trying to create. Think of it less like buying a product off the shelf and more like commissioning a custom piece of architecture. The final price tag is shaped by your vision, your timeline, and the technical requirements needed to bring it to life.

Understanding the key cost drivers from the start helps you set realistic expectations for your team and your clients. It also allows you to make strategic decisions about where to invest your budget for the biggest impact. The most significant factors are the complexity of the product, the timeline for delivery, and the specific materials and engineering expertise required. By breaking down your project along these lines, you can work with a design partner to get a much more accurate estimate and avoid surprises down the road. It’s all about balancing the creative vision with the practical realities of development, a common challenge in any new product development process.

Project Complexity and Scope

The single biggest factor influencing cost is the complexity of your product. Designing a simple piece of branded merchandise, like a custom bottle opener, is straightforward. It requires concept sketching, 3D modeling, and basic manufacturing prep. But designing an interactive smart device for an experiential campaign involves layers of complexity: electronics integration, user interface design, and intricate mechanical assemblies. The more parts, features, and technical challenges involved, the more hours of design and engineering are required.

Scope is the other side of this coin. Are you asking for initial concept sketches to pitch a client, or do you need a full suite of services, from research and prototyping to production-ready engineering files? A broader scope naturally requires a larger investment.

Timelines and Key Deliverables

In the agency world, deadlines are everything. While a good design firm can work quickly, accelerated timelines often come at a premium. Rush projects may require the team to work overtime or reallocate resources from other projects, which is reflected in the cost. The best way to manage this is to engage a design partner as early as possible in your campaign planning.

Clear deliverables are also crucial for keeping costs in check. A project with a vague brief and shifting goals will inevitably lead to extra revisions and expanded scope. A structured approach with well-defined phases and sign-offs ensures everyone is aligned and the project stays on track, preventing budget creep and keeping the focus on executing the core vision efficiently.

Material, Prototyping, and Engineering Needs

The physical nature of your product directly impacts the budget. Your choice of materials—whether it’s recycled plastics, machined aluminum, or custom-molded silicone—will influence the design process and manufacturing costs. Prototyping is another key expense. A simple 3D-printed model for form and feel is relatively inexpensive, but a fully functional, looks-like-works-like prototype with integrated electronics requires a much larger investment.

Finally, specialized engineering is a significant cost driver. If your product has moving parts, requires thermal management, or contains a custom circuit board, you’ll need mechanical and electrical engineers on the team. Addressing these feasibility issues early ensures the final product is not only beautiful but also functional and reliable.

What Deliverables Should You Expect?

When you partner with an industrial design firm, the process is all about turning a creative brief into a tangible, real-world product. The outputs you receive are more than just pretty pictures; they are the essential assets that bridge the gap between an idea and a factory-ready design. These deliverables serve as your project’s roadmap, ensuring every stakeholder—from your client to the manufacturer—is perfectly aligned.

Think of these deliverables as a toolkit for production. They provide the technical precision needed to manufacture a product consistently and at scale, which is critical whether you’re creating a high-tech device for a startup or a custom influencer kit for a global brand. Each document and model is a checkpoint, a confirmation that the design is not only visually compelling but also functional, feasible, and ready for the real world. Understanding what to expect will help you manage client expectations and guide your project smoothly from kickoff to final delivery.

CAD Models and Technical Drawings

At the heart of any modern product development project are the CAD (Computer-Aided Design) models. These are the highly detailed, three-dimensional digital blueprints of your product. A CAD model defines every single surface, curve, and component with mathematical precision, allowing you to see exactly how the product will look from any angle. Paired with these are technical drawings—the 2D schematics that manufacturers use on the factory floor. These drawings call out specific dimensions, materials, tolerances, and assembly notes, leaving no room for interpretation. For an agency, these files are invaluable for securing accurate manufacturing quotes and ensuring the final product is a perfect reflection of your creative vision.

Prototypes and Proof-of-Concept Models

Before you commit to thousands of units, you need to hold the product in your hands. Prototypes are physical models that allow you to test a design’s form, fit, and function. They can range from simple proof-of-concept models that validate a core mechanism to high-fidelity appearance models that look and feel just like the final product. For agencies, prototyping is a critical step for getting client sign-off, creating assets for launch campaigns, or conducting user testing. It’s the best way to catch potential issues early and confirm that the user experience is exactly what you intended before investing in expensive production tooling.

Manufacturing Documentation and Specs

Once the design is finalized and the prototype is approved, your industrial design partner will prepare a complete package of manufacturing documentation. This goes beyond the CAD files and includes everything a factory needs to produce your product flawlessly. A key part of this is the Bill of Materials (BOM), which is an itemized list of every single part, from screws and enclosures to electronic components and packaging materials. This "tech pack" also includes specifications for colors (using systems like Pantone), materials, and finishes (e.g., matte, gloss, textured). This comprehensive documentation ensures quality control and brand consistency, guaranteeing the thousandth unit looks and works just as perfectly as the first.

Common Challenges to Prepare For

Bringing a physical product to life is an exciting process, but it comes with its own unique set of hurdles. Unlike a digital campaign that can be tweaked on the fly, a physical product involves materials, mechanics, and manufacturing realities that are much harder to change once the process is in motion. Knowing what to expect can make the entire journey smoother for you, your team, and your client. Think of these challenges less as roadblocks and more as checkpoints that, with the right partner, you can move through with confidence and clarity.

The most common issues that pop up in product development aren't surprises to an experienced design and engineering team. They usually fall into three main categories: getting everyone aligned on the project goals, making sure a creative idea can actually be produced, and keeping the project on track and everyone in the loop. For agencies used to rapid iteration, these physical constraints can feel new. A great industrial design partner doesn’t just design the product; they act as your guide, helping you anticipate these challenges and build a plan to address them from the very beginning. This proactive approach is what separates a stressful, budget-breaking project from a successful one that delivers on time and wows your client.

Defining Clear Project Requirements

The most creative concept can get derailed if the goals aren't crystal clear from the start. Before any design work begins, it’s essential to establish well-defined project requirements. This is the foundation of the entire project. For agencies, this feels a lot like a creative brief, but with added layers: Who is the end-user? What problem does this product solve for them? What are the must-have features versus the nice-to-haves? What does success look like for your client? Answering these questions upfront prevents misunderstandings and ensures the final product meets the intended goals. A good design firm will lead this discovery process, asking the tough questions to help you build a solid strategic framework.

Balancing Innovation with Manufacturing Feasibility

You’re experts at dreaming up big, memorable ideas. The challenge is translating that vision into a physical object that can be manufactured reliably and within budget. This is where creativity meets practicality. An idea might look incredible in a render, but if it requires an impossible-to-source material or a complex assembly process, it can stall out before it ever gets made. This is why Design for Manufacturing (DFM) is so critical. An experienced engineering and design partner will work with you to refine your concept, finding clever ways to achieve your aesthetic and functional goals while keeping the realities of production in mind from day one.

Managing Timelines and Stakeholder Expectations

Agency timelines are often fast, but physical product development operates on a different clock. Prototyping, tooling for manufacturing, and shipping all require lead time that needs to be baked into your project plan. One of the biggest challenges is aligning these production timelines with your client’s campaign launch dates. This requires clear and consistent communication to manage everyone’s expectations. Your industrial design partner should provide a realistic timeline and be transparent about potential delays. Effective stakeholder management ensures that you, your client, and the development team are all on the same page, preventing last-minute surprises and keeping the project moving forward smoothly.

Key Trends Shaping Industrial Design

The world of product design is always moving, shaped by new technologies, consumer values, and creative possibilities. For agencies, staying aware of these shifts is key to creating physical products and campaign assets that feel fresh, relevant, and genuinely impressive. These aren’t just buzzwords; they are powerful tools you can use to build more meaningful connections between a brand and its audience. Understanding these trends helps you move beyond standard merchandise and create experiences that capture attention and tell a compelling story. From materials that respect the planet to products that interact with the digital world, here are the key trends shaping modern industrial design.

Sustainable and Eco-Friendly Design

Today, sustainability is a core expectation. Consumers are more aware than ever of a product’s environmental impact, and a disposable promotional item can do more harm than good for a brand’s image. This trend is about designing with the entire product lifecycle in mind—from sourcing renewable or recycled materials to planning for responsible disposal. It means asking questions like: Can this be easily disassembled for recycling? Are we using non-toxic finishes? Can we reduce packaging waste? For agencies, this is a huge opportunity to align a physical product with a brand’s values, creating something people feel good about owning and using. It’s about designing with intention and proving a brand’s commitment to a healthier planet.

Smart Tech and IoT Integration

Products are no longer just static objects; they can be gateways to digital experiences. The integration of smart technology and the Internet of Things (IoT) allows us to embed sensors, chips, and connectivity into everyday items. Imagine an influencer kit where the packaging unlocks an augmented reality filter, or a piece of branded merchandise that connects to an app to offer exclusive content. This trend transforms a physical product from a simple takeaway into an interactive, engaging touchpoint. By building smart technology into your designs, you can create memorable, high-impact experiences that extend the campaign’s reach long after the initial launch and deepen the user’s connection to the brand.

Generative Design and Advanced Manufacturing

This is where design gets truly futuristic. Generative design uses AI to explore thousands of design possibilities based on goals you set, like weight, strength, and material use. The result is often complex, organic-looking structures that would be nearly impossible for a human to conceive of alone. When paired with advanced manufacturing methods like 3D printing, these intricate designs can be brought to life. For an agency, this opens the door to creating visually stunning, one-of-a-kind products that feel like they’re from the future. It’s perfect for high-end promotional items, custom awards, or any project where the goal is to create something utterly unique that stops people in their tracks.

Which Industries Benefit Most from Industrial Design?

Industrial design is a versatile discipline that touches almost every product you interact with daily. From the ergonomic handle of your coffee mug to the sleek interface of your smartphone, its principles are everywhere. But while its reach is broad, some industries rely on it more than others to innovate, compete, and connect with users. For creative agencies, understanding these key sectors can unlock new opportunities to build immersive, physical experiences for your clients that go far beyond a digital campaign.

The common thread across these industries is the need to solve complex problems by balancing aesthetics, functionality, and manufacturability. In some fields, the user experience is the primary differentiator in a crowded market. In others, design is critical for safety, usability, and brand identity. Whether it’s a high-tech wearable, a stunning influencer kit, or a piece of iconic furniture, industrial design is the bridge between a great idea and a real-world product that people love. Exploring these applications can help you see how physical products can become a powerful part of your next creative strategy, turning abstract brand concepts into tangible assets that create lasting engagement.

Consumer Electronics and Medical Devices

Nowhere is the blend of form and function more critical than in consumer electronics and medical devices. In the tech world, a product’s success often hinges on its user experience. Think about the intuitive feel of a gaming controller or the seamless design of a smart home device. Industrial design ensures these products are not only beautiful but also easy and enjoyable to use. It’s what separates a clunky gadget from a device that feels like a natural extension of the user.

Similarly, the medical field depends on human-centered design to create products that are safe, effective, and intuitive. For a surgeon holding a new tool or a patient using an at-home monitoring device, clear and ergonomic design can reduce errors and improve outcomes. In both industries, industrial design isn’t just a finishing touch—it’s a core component of the product’s value.

Packaging and Branded Experiences for Agencies

For creative and advertising agencies, industrial design is a powerful tool for bringing brand stories to life. It’s not just about the product itself, but the entire ecosystem around it. Think about influencer kits with intricate, multi-layered packaging or custom-designed merchandise that feels premium and unique. These physical touchpoints create memorable unboxing experiences that generate buzz and deepen brand loyalty in a way a digital ad simply can’t.

This is where an industrial design partner becomes invaluable. We can help you move beyond standard promotional items and develop truly bespoke physical assets for your campaigns. Whether it’s designing a unique bottle for a new beverage or engineering a complex, interactive mailer, we translate your creative vision into a manufacturable reality that makes a lasting impression.

Automotive and Furniture Design

The automotive and furniture industries are classic examples of where industrial design has long been a driving force. When you look at a car, you’re seeing more than just a mode of transportation; you’re seeing a carefully crafted identity. Industrial designers shape a vehicle’s exterior lines for aerodynamics and visual appeal, while also designing an interior that is comfortable, intuitive, and safe for the driver. Every curve and material choice is intentional.

Furniture design follows similar principles, balancing aesthetics with ergonomics and durability. A well-designed chair isn’t just a beautiful object—it supports the human body correctly and is built to last. In both fields, designers work to create an emotional connection with the user, turning everyday objects into sources of comfort, pride, and delight. This deep understanding of emotional design is what makes products in these sectors so iconic.

How to Get Started with an Industrial Design Partner

Ready to turn that brilliant campaign idea into a physical product? Partnering with an industrial design firm is the first step, and how you start the relationship sets the tone for the entire project. It’s less about having a perfect, fully-formed concept and more about being prepared to collaborate. A great design partner doesn’t just execute your vision; they help you refine it, making sure it’s not only beautiful and on-brand but also functional, manufacturable, and ready for the real world. By bringing the right information and mindset to the table from day one, you can ensure a smooth process that transforms your creative brief into a tangible product your client—and their audience—will love.

The goal is to build a partnership, not just a transaction. This means involving your design and engineering experts early to identify potential challenges and opportunities you might not see. When you integrate industrial design from the beginning, you can make smarter decisions about materials, mechanics, and costs before you’re too far down the road. Think of your design firm as an extension of your creative team—an expert partner ready to solve technical challenges so you can focus on the big picture. The following steps will help you kick off the project with clarity and confidence, setting everyone up for success.

1. Clarify Your Creative Brief and Business Goals

Before you pick up the phone, get your internal thoughts organized. A strong creative brief is your project’s north star. It should clearly outline the "what" and the "why." What is this product? Is it a piece of high-end influencer merch, a tech gadget for a pop-up experience, or custom packaging for a product launch? More importantly, why are you creating it? Define the business objectives. Are you trying to drive brand loyalty, generate social media buzz, or create a new revenue stream? Be sure to include details about your target audience, brand guidelines, and any must-have features or functional requirements. This clarity helps a design firm understand your vision and propose a solution that truly fits.

2. Engage a Partner Early in the Creative Process

It’s tempting to fully flesh out an idea before bringing in an outside partner, but with physical products, it’s best to engage an industrial design firm early. Bringing them in while your concept is still flexible allows their expertise to shape the outcome for the better. They can provide immediate feedback on what’s technically feasible, suggest innovative materials, and design for manufacturing from day one. This proactive approach helps you avoid costly redesigns later and ensures the final product is both imaginative and practical. An early partnership allows you to balance creative ambition with real-world constraints, leading to a stronger, more successful outcome.

3. Prepare for a Productive Kickoff Meeting

Your first meeting is all about alignment. To make it as productive as possible, come prepared with your creative brief and any visual inspiration you have, like mood boards or rough sketches. It’s also helpful to discuss your constraints openly. Be ready to talk about your ideal timeline, budget range, and any non-negotiables. The more context you can provide, the better your potential partner can tailor their approach. This initial conversation is a two-way street; it’s your chance to see how they think and their chance to understand your goals. A successful project depends on building strong relationships and transparent communication from the very start.

4. Align on Communication and Workflow

Once you’ve chosen a partner, the final step before diving in is to align on how you’ll work together. As an agency, you’re likely managing a client relationship, so a clear process is essential. Discuss who the main points of contact will be on both sides. Establish a regular cadence for check-ins and updates, whether it’s a weekly call or a shared project management board. You should also clarify the feedback and approval process. Understanding how design revisions are handled and when key decisions need to be made will keep the project on track and prevent surprises. A well-defined workflow ensures everyone stays in sync from concept to production.

Related Articles

10 Best Industrial Design Agencies for Product Innovation — Jackson Hedden

Industrial Design vs Product Design: Key Differences — Jackson Hedden

Top Industrial Design Firms: How to Choose the Best Partner | Jackson Hedden Inc

Frequently Asked Questions

Why should our agency use industrial design instead of just putting our client's logo on a pre-made item? Think of it as the difference between a generic greeting card and a handwritten letter. Putting a logo on a stock item is easy, but it rarely creates a memorable experience. Custom industrial design allows you to create a physical product that tells your client's brand story in its form, function, and feel. It transforms a simple piece of merchandise into a thoughtful brand artifact that people will actually want to keep and talk about, creating a much deeper and more lasting connection than a disposable piece of swag ever could.

At what point in our creative process should we bring in a design partner? The short answer is as early as possible, ideally when you're still in the brainstorming phase. Bringing a design and engineering partner in early doesn't limit your creativity; it strengthens it. We can provide immediate feedback on what’s technically possible and suggest innovative approaches you might not have considered. This early collaboration ensures your big idea is built on a solid, manufacturable foundation, which saves a huge amount of time and prevents costly redesigns down the road.

What if our idea is more of a creative concept than a fully-formed product? Is that enough to start with? Absolutely. A strong creative concept is the perfect starting point. You bring the "what" and the "why," and we'll help you figure out the "how." Our job is to take that initial spark of an idea and work with you to translate it into a functional, beautiful, and producible object. The initial phase of any project involves exploring, sketching, and refining the concept, so you definitely don't need to have all the answers before you come to us.

How do you make sure our creative vision doesn't get lost in all the technical engineering details? This is a core part of our job. We see ourselves as translators who ensure the creative intent is the driving force behind every technical decision. The process is a constant conversation between your team and ours. We don't just take your brief and disappear. Instead, we present you with solutions and options at every stage, explaining how different engineering choices will impact the final look, feel, and user experience. Our goal is to use engineering to bring your vision to life, not compromise it.

Can you give us a rough idea of how long a typical project takes from concept to production-ready files? The timeline for a project depends entirely on its complexity. A simple, non-electronic product might move from concept to manufacturing handoff in a matter of weeks. However, a complex smart device with custom electronics and intricate mechanics could take several months of design, prototyping, and testing. The key factors that influence the schedule are the product's complexity, the number of prototyping rounds needed for refinement, and how quickly decisions can be made. We always provide a detailed project plan upfront so you know exactly what to expect.