Quality Checkpoints 101: A Practical Guide

In manufacturing, there’s a simple principle known as the 1-10-100 Rule. It states that it costs $1 to prevent a problem, $10 to correct it during production, and $100 to fix it after it has reached the customer. For a creative agency, that $100 could mean reprinting an entire run of custom packaging or recalling a faulty piece of merchandise. The financial and reputational risks are massive. This is why smart teams don't leave quality to chance. They build a system of quality checkpoints into their process from day one, catching small issues before they become budget-breaking disasters.

Key Takeaways

- Proactive checks prevent reactive fixes: Build quality checkpoints into your project timeline from the beginning to catch small issues before they become costly, time-consuming disasters.

- Establish clear standards and assign ownership: You can't check for quality without defining it first. Document your exact requirements and assign a specific person to approve each step to create accountability.

- Use feedback to make your process smarter: Don't just set and forget your checkpoints. Track simple metrics and review what worked after each project to continuously refine your workflow and deliver better results over time.

What Is a Quality Checkpoint?

Think of a quality checkpoint as a planned pit stop in your product development journey. It’s a specific point in the process—whether in design, engineering, or manufacturing—where you pause to inspect the work and make sure it meets the standards you’ve set. This isn’t about a single, final once-over before everything ships. Instead, it’s a series of intentional checks built into the project timeline.

For creative agencies, these checkpoints are your best defense against a final product that misses the mark. They ensure the physical item not only functions perfectly but also matches the creative vision your team sold to the client. From verifying the Pantone color on a prototype to testing the durability of a custom mailer box, each check confirms you’re still on the right track. It’s how you move from a brilliant concept to a tangible product without any unwelcome surprises at the finish line.

The Core Purpose of a Quality Check

At its heart, a quality check is about making sure the final product delivers on its promise. It’s a systematic way to confirm that every detail aligns with client expectations and your own creative standards. The goal is to maintain the integrity of the product from the initial sketch all the way to the unboxing experience. This is where you catch potential issues, like a logo that’s slightly off-center or a material that doesn’t feel as premium as it looked in the render.

To keep everyone aligned, teams often use quality control checklists as a guide during inspections. These documents outline every critical detail that needs to be verified, from functional requirements to aesthetic finishes. This simple tool ensures that nothing gets overlooked and that the product you deliver is a flawless representation of your agency’s vision and your client’s brand.

The Real Cost of Skipping a Check

Ignoring quality checkpoints might feel like you’re saving time, but it almost always costs you more in the long run—and not just in money. A flawed product can damage your agency’s reputation, erode client trust, and create last-minute fire drills that burn out your team. The real cost is the frantic, expensive effort to fix a problem that could have been easily prevented.

There’s a simple principle in manufacturing known as the 1-10-100 Rule. It states that it costs $1 to prevent a problem, $10 to correct it during production, and $100 to fix it after it has reached the customer. Imagine catching a typo on a packaging design before it goes to print versus having to recall and replace thousands of units. The difference is massive. Investing in production line quality checks isn't an extra expense; it's one of the smartest ways to protect your budget, your timeline, and your relationship with the client.

Common Types of Quality Checkpoints

Quality checkpoints aren’t a one-size-fits-all solution. They look different depending on what you’re creating, whether it’s a physical product, a mobile app, or a customer experience. The core idea, however, remains the same: to systematically verify that your work meets a defined standard at critical stages. Understanding how checkpoints function in various fields can help you see where they fit into your own projects, especially when you’re bridging the gap between a creative idea and a tangible outcome. Let's break down what these look like in a few key areas.

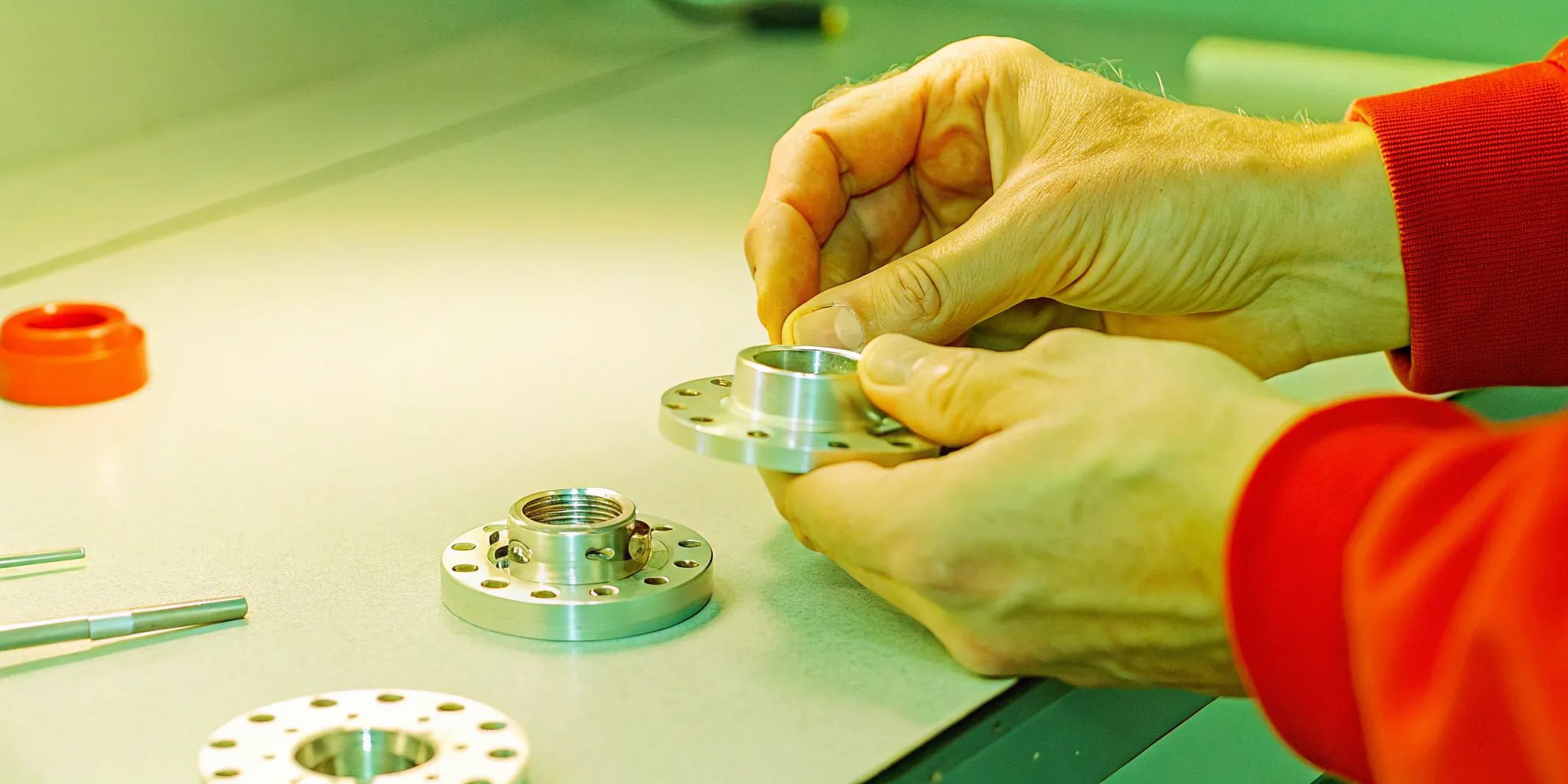

In Manufacturing

When you’re making physical goods, quality checkpoints are all about hands-on inspection. Think of an assembly line. At specific points, a product is pulled aside and checked to ensure it meets all the required specifications. This could involve measuring dimensions, testing functionality, or checking for cosmetic flaws. The goal of these quality control measures is to catch defects early, before a small mistake gets repeated thousands of times. This prevents waste and ensures the final product that lands in a customer's hands is exactly what you promised.

In Software Development

In the digital world, checkpoints are built into the development process as a series of tests. Instead of a physical inspection, developers and QA teams run checkpoint testing to make sure the code works as expected. These checks can verify that a new feature doesn’t break an old one (integration tests), confirm the app can handle a lot of users at once (performance tests), or simply ensure a button does what it’s supposed to do. Each test is a checkpoint that confirms the software is stable and functional before it moves to the next stage or gets released to users.

In the Service Industry

You can’t physically inspect a service, so quality checkpoints here focus on consistency and customer experience. This might involve monitoring customer support calls to ensure agents are helpful and on-brand, using mystery shoppers to evaluate the in-store experience, or tracking response times for customer inquiries. The goal is to ensure every customer interaction meets a high standard. These checkpoints are designed to find gaps in service delivery and training, helping the business maintain a consistently positive reputation and keep customers happy.

In Product Design and Engineering

For us, this is where everything comes together. In product design and engineering, checkpoints are integrated from the very beginning. They aren't just a final inspection; they are crucial milestones in the development process. This includes reviewing initial sketches, validating material choices, and running simulations on 3D CAD models before a single physical part is made. A well-designed process with clear checkpoints enables teams to build better products, faster. It’s about making smart decisions early to ensure the final product is not only beautiful and functional but also ready for manufacturing without costly surprises.

The Payoff: How Quality Checks Improve Your Project

It’s easy to think of quality checkpoints as extra steps that slow down a project. When you’re working on a tight deadline for a client campaign, the last thing you want is another review cycle. But in reality, a smart quality control process does the opposite—it protects your timeline, your budget, and your client’s reputation. Think of it as a safety net that catches small issues before they become project-ending disasters.

For agencies venturing into physical products, whether it's a piece of high-tech merch or custom packaging for an influencer kit, the stakes are high. Unlike a digital asset that can be patched or updated, a physical product is final once it ships. Implementing checkpoints throughout the design and production process isn’t about adding bureaucracy; it’s about ensuring the tangible thing you hand over is a perfect reflection of the creative vision. It’s how you guarantee that what looked amazing in the CAD file feels just as impressive in your client’s hands. This proactive approach is what separates a smooth, successful project from a costly, stressful one.

Catch Mistakes Early to Save Money

Finding a design flaw during the initial prototyping phase might cost a few hundred dollars and a couple of days to fix. Finding that same flaw after 10,000 units have been manufactured can sink an entire campaign. Quality checkpoints are designed to catch these issues at the earliest, cheapest possible stage. By inspecting and testing at key milestones, you can correct course before committing to expensive tooling or large material orders. The cost of poor quality can be staggering, with some companies spending 15% to 20% of their revenue just to fix mistakes. A few well-placed checks can prevent your project from becoming part of that statistic.

Reduce Rework and Waste

Rework doesn’t just burn through your budget; it wastes time and physical materials. A single checkpoint before production kicks off can prevent an entire batch of products from being manufactured with the wrong color, material, or dimensions. Inspections at each stage of the process help find and fix problems before they get replicated thousands of times over. This is a core principle of Design for Manufacturability (DFM), where potential production issues are designed out of the product from the start. The goal is to get it right the first time, minimizing scrap and ensuring the final output is consistent and high-quality.

Protect Your Brand and Keep Clients Happy

For your client, the physical product you create is a direct reflection of their brand. A flimsy enclosure, a buggy electronic component, or a package that’s difficult to open can instantly damage their reputation. Quality control is ultimately about protecting that brand experience and delivering on the promise you made to your client. When the final product works flawlessly and feels premium, it reinforces brand value and strengthens customer loyalty. Consistently delivering high-quality results not only keeps your current clients thrilled but also builds your agency’s reputation as a team that can execute complex, tangible ideas without a hitch.

How to Set Up Quality Checkpoints That Work

Putting effective quality checkpoints in place is less about adding red tape and more about building a smart safety net for your project. It’s about creating a clear, repeatable process that ensures the physical product you envisioned is the one that gets delivered—without any last-minute surprises. When you’re an agency juggling creative vision, client expectations, and production realities, a solid checkpoint system is your best friend. It turns a potentially chaotic process into a predictable one by catching issues early, keeping everyone aligned, and protecting the final product's integrity. The goal isn’t to slow things down; it’s to move forward with confidence, knowing every detail is being tracked and verified along the way. Here’s how you can set up a system that works for you and your partners.

Define Clear Standards from the Start

You can't hit a target you can't see. Before any work begins, you need to define exactly what "quality" means for your specific project. This goes beyond a general idea of "it should look good." Get specific. What are the exact Pantone colors? What are the acceptable tolerances for dimensions? What material finish is required? Creating a detailed product requirements document (PRD) is the first and most critical step. This document becomes your single source of truth, ensuring that your creative team, your client, and your engineering partner are all working toward the same measurable goals. Clear standards remove ambiguity and make every subsequent quality check a simple yes-or-no question.

Get Everyone on the Same Page

Once you’ve defined your standards, you need to make sure everyone involved understands them. Quality isn't one person's job; it's a collective responsibility. Your creative director, account manager, and engineering team should all be familiar with the project's quality requirements. When everyone shares a clear understanding of the objectives, they become active participants in the quality process. This fosters a culture where anyone on the team feels empowered to flag a potential issue, rather than assuming someone else will catch it. This alignment is key to identifying problems early and keeping the project on track without unnecessary friction.

Train Your Team and Assign Ownership

With standards set and communicated, the next step is to assign clear ownership for each checkpoint. Who has the final say on the prototype's finish? Who is responsible for signing off on the packaging artwork before it goes to print? Assigning a specific person to each checkpoint creates accountability and ensures that nothing gets overlooked. This isn't about micromanagement; it's about clarity. When team members understand their specific roles in the quality process, they can focus on their responsibilities. This simple act of assigning ownership dramatically reduces the risk of miscommunication and ensures that every critical detail is reviewed by the right person at the right time.

Build Checkpoints into Every Project Stage

Quality checks shouldn't be saved for the very end. The most effective approach is to integrate them throughout the entire product development lifecycle. Think of them as gates that must be passed before moving to the next phase. Schedule checkpoints after key stages like initial design, 3D modeling, prototyping, and the first article inspection from the factory. This proactive method allows you to catch and correct issues when they are still small and inexpensive to fix. Waiting until the final production run to spot a mistake can lead to costly rework and significant delays. By building checks into your project timeline, you ensure quality is maintained from start to finish.

Use Feedback to Get Better Over Time

Your quality assurance process should be a living system, not a static document. After each project wraps up, take the time to review how your checkpoints performed. What worked well? Where were the bottlenecks? Did a specific check catch a critical error? Or did another one prove to be unnecessary? Creating a feedback loop is essential for continuous improvement. Use the lessons from one project to refine your process for the next. This iterative approach not only makes your workflow more efficient over time but also demonstrates a commitment to excellence that clients will notice and appreciate.

Common Roadblocks (And How to Handle Them)

Even the best-laid plans can hit a few snags. Implementing quality checkpoints is a smart move, but it’s not always a perfectly smooth process. Anticipating the common challenges will help you address them head-on, keeping your project on track and your team aligned. Most issues come down to people, pacing, and process. Here’s how to handle the most frequent roadblocks you’ll encounter.

Getting Your Team On Board

Let’s be honest: no one loves a new process, especially when deadlines are tight. You might face some initial pushback when you introduce quality checkpoints. The key is to frame it as a supportive tool, not a bureaucratic hurdle. Start by getting leadership to champion the process. When leaders model the behavior and explain the why behind it, it’s easier for everyone else to get on board. Fostering a culture of change management helps your team feel secure and understood, which is crucial for getting genuine buy-in instead of just reluctant compliance.

Balancing Speed with Quality

In the agency world, speed is everything. There’s a natural fear that adding more steps will slow things down, but that’s a misconception. True efficiency isn’t just about moving fast; it’s about moving forward without having to double back. Quality checkpoints are your insurance against costly, time-consuming revisions later. A well-structured product development process builds in moments for review, ensuring you catch small issues before they become major delays. Think of it as a quick pit stop to make sure you’re still heading in the right direction, preventing a much longer detour down the road.

Working Within Your Budget

Every project has a budget, and it’s easy to see quality checks as an added expense. In reality, they are one of the best ways to protect your bottom line. The cost of a small amount of time for a design review is nothing compared to the cost of re-tooling for manufacturing or reprinting thousands of units of packaging. To make it work, you have to allocate resources for quality from the start. This includes time for training your team on the standards and providing them with the right tools. This upfront investment pays for itself by preventing waste and rework.

Keeping the Process Lean, Not Bloated

The goal of quality checkpoints is not to create a mountain of paperwork or endless meetings. A common pitfall is getting bogged down in theory and over-documentation, which drains creative energy. Your quality management system should be practical and streamlined. Focus on what actually adds value and helps the team make better decisions. Prioritize clear, actionable feedback over filling out forms. By keeping your processes lean, you ensure that your quality checks remain an effective tool that supports the project instead of a bloated system that gets in the way.

Using Tech to Improve Your Quality Checks

Let’s be honest: manual quality checks can feel tedious. Ticking boxes on a clipboard is slow, prone to human error, and doesn’t give you much insight beyond a simple pass or fail. The good news is that technology can transform your quality process from a necessary chore into a strategic tool that saves time, money, and headaches. By bringing the right tech into the mix, you can make your checkpoints faster, more accurate, and way more insightful.

For creative agencies managing the production of a physical product—whether it's a high-tech device for a campaign or a custom-molded piece of packaging—technology provides a crucial layer of oversight. It helps bridge the gap between your creative vision and the realities of manufacturing. Instead of waiting for a finished prototype to find a flaw, you can use digital tools to monitor progress, catch deviations from the design in real-time, and collect data that proves the final product is exactly what you and your client signed off on. This isn’t about replacing people; it’s about giving your team superpowers to ensure every detail is perfect.

Automated Inspection and Testing

Some quality checks are repetitive and require a level of precision that’s tough for the human eye to maintain consistently. This is where automated inspection comes in. Think of tools like 3D scanners that compare a physical part to its original CAD model down to the micron, or camera systems that use computer vision to spot cosmetic defects on an assembly line. For mechanical products, we can build custom rigs that automatically test functions like button presses or hinge movements thousands of times to simulate long-term use. This level of quality inspection is a non-negotiable checkpoint for ensuring every single product meets the standard, not just the first one off the line.

Data and Analytics Tools

A paper checklist tells you if something passed or failed. A digital checklist tells you why. When you use digital tools to manage your quality checkpoints, every piece of feedback becomes a data point. Over time, this data can reveal trends you’d otherwise miss. You might discover that a specific part from one supplier fails more often than others, or that a certain assembly step is a consistent bottleneck. This information is gold. It allows you to make data-driven decisions to refine your design, improve your manufacturing process, and prevent future problems before they start. For your clients, it provides transparent, concrete evidence of the quality built into their product.

Real-Time Project Monitoring

Waiting until the end of a production run to check for quality is a recipe for expensive rework. Modern tools allow you to monitor progress in real time, so you can catch issues the moment they happen. This can be as simple as a shared project management dashboard with built-in QA tasks or as advanced as using sensors on the factory floor to track tolerances. The principle is similar to checkpoint testing in software, where you constantly compare the actual result to the intended design. This approach gives you the power to make immediate adjustments, ensuring the final product is a perfect match for the approved design and functions exactly as planned.

Integrating with Your Current Workflow

The most effective technology is the kind that fits seamlessly into how your team already works. Instead of forcing everyone to learn a new, isolated system, you can integrate quality checks directly into your existing project management tools like Asana, Jira, or Slack. When a design is ready for review, a task can automatically be assigned to the right person. When a prototype fails an inspection, a notification can be sent to the project channel instantly. This integration provides complete visibility into the quality assurance process, making quality a shared, transparent responsibility. It keeps the entire team accountable and ensures that these crucial checks never fall through the cracks.

How to Know If Your Checkpoints Are Working

Setting up quality checkpoints is a great first step, but it’s only half the job. How do you know if they’re actually making a difference? Without a way to measure their impact, your checkpoints are just another box to tick on a long to-do list. The goal isn’t just to have a process; it’s to have a process that actively prevents errors, saves time, and delivers a better final product for your client.

The good news is that you don’t have to guess. By paying attention to a few key areas, you can get a clear picture of what’s working and what needs a tune-up. It comes down to tracking the right numbers, looking for trends, reviewing your process regularly, and keeping solid records. Think of it as applying the same data-driven mindset you use for campaign performance to your own internal workflow. When you can see tangible proof that your checkpoints are catching issues and improving outcomes, you’ll know you’re on the right track.

Key Metrics to Track

You can't improve what you don't measure. To see if your checkpoints are effective, you need to track key metrics related to quality. These numbers give you an objective look at your performance and help you spot areas for improvement before they become major problems. Checkpoints ensure each product meets required quality standards, and by inspecting deliverables at specific stages, you can gather the data you need to evaluate your quality performance.

Start by identifying a few simple KPIs. For physical products, a great one is First Pass Yield (FPY), which measures the percentage of items that make it through a checkpoint correctly the first time, without any rework. You can also track scrap rate or client revision requests. The specific metrics will depend on your project, but the principle is the same: turn quality into a number you can watch and improve over time.

Tracking a Reduction in Defects

The most straightforward sign that your checkpoints are working is a drop in the number of defects. When you catch mistakes early in the design or prototyping phase, they don't have a chance to snowball into bigger, more expensive problems down the line. Quality inspection is one of the main tools manufacturers use to ensure standards are met, and tracking defect rates can provide clear insights into the effectiveness of your process.

Keep a simple log of the issues found at each checkpoint. Note the type of defect, where it occurred, and its severity. Over time, you’ll start to see patterns. Maybe a specific file handoff consistently causes issues, or a certain material doesn’t perform as expected. This data allows you to move beyond just fixing individual errors and start addressing the root cause, leading to a sustainable reduction in defects across all your projects.

Conducting Regular Audits

A quality checkpoint system needs its own check-up every now and then. That’s where audits come in. An audit is simply a structured review of your process to make sure it’s being followed correctly and is still effective. It’s your chance to step back and ask, "Are we doing what we said we would do? And is it still the best way to do it?"

Conducting regular audits helps ensure that your quality checkpoints are being used consistently and that any deviations are identified and addressed promptly. You can do this quarterly or after a major project wraps. Talk to your team, review the documentation, and look at the defect data you’ve been collecting. This isn’t about assigning blame; it’s about finding opportunities to refine your workflow, provide better training, or update your standards.

The Importance of Good Documentation

If your quality process only lives in someone’s head, it’s not a process—it’s a habit that could walk out the door at any time. Good documentation is essential for creating a reliable quality system. It provides a clear, shareable record of your standards, methods, and outcomes, which is crucial for consistency and continuous improvement. When everyone is working from the same playbook, you reduce ambiguity and ensure every project gets the same level of attention.

Your documentation doesn’t need to be a novel. Start with a simple checklist for each checkpoint, outlining what needs to be verified. Record who performed the check, when it was done, and what the results were. This creates a transparent record that keeps the team accountable and gives you a valuable history to reference for future projects. This clear record of processes is your foundation for building a scalable and repeatable quality workflow.

Related Articles

- Private Label Product Design: A 7-Step Guide

- What is Embedded Product Design? A Full Guide

- Manufacturing Quality Control: Ensuring Excellence at Every Step — Jackson Hedden

- Prototype to Production: An Agency's Guide — Jackson Hedden

- Medical Device Design: The Complete 2025 Guide — Jackson Hedden

Frequently Asked Questions

Won't adding all these checkpoints slow down our fast-paced projects? It’s a common concern, but it’s actually the opposite. Think of checkpoints as a way to protect your timeline, not slow it down. A quick review of a prototype might add a day to the schedule, but it prevents the weeks-long delay that comes from discovering a major flaw after thousands of units have already been produced. True speed is about moving forward without having to double back, and these checks ensure you’re always heading in the right direction.

We're new to physical products. What's the single most important first step? Start by defining exactly what "done right" looks like. Before you even think about production, create a simple document that lists all the critical requirements for the product. This should include specific details like exact colors, materials, dimensions, and functional needs. This document becomes your guidepost, ensuring everyone—your team, your client, and your engineering partner—is aiming for the same target from day one.

Who is responsible for managing these quality checks? Quality is a team sport, but each player has a specific role. Your agency is typically responsible for signing off on creative and brand-related elements, like color and finish. Your engineering partner, like us, handles the technical verification to ensure the product is functional and manufacturable. The client gives the ultimate approval at key milestones. The key is to assign a clear owner for each specific checkpoint so nothing gets missed.

Isn't one big inspection before shipping enough? Relying on a single final inspection is a huge gamble. By that point, your entire production run is complete. If you find a mistake, your only options are to ship a flawed product or absorb a massive loss on rework and delays. By integrating checks throughout the process, you catch issues when they are small, cheap, and easy to fix. It’s the difference between correcting a typo in a document and recalling a published book.

Do we really need a formal process for a small project like an influencer kit? Absolutely. The process doesn't have to be complicated, but it does need to exist. Even for a "simple" project, a lot can go wrong—the custom box might not close properly, the printed color could be off, or the product might not fit securely in its insert. A few simple checkpoints, like reviewing a production sample of the packaging, can prevent the kind of embarrassing mistake that undermines an entire campaign. The scale of the process should match the scale of the project, but you should never skip it entirely.