Rapid Tooling Services: A Guide to Faster Product Launches

The most memorable brand experiences are often the ones we can touch and feel. While digital campaigns are essential, creating a physical touchpoint—whether it’s a sophisticated piece of packaging or a custom-designed gadget—can leave a lasting impression. The challenge, however, is that manufacturing can seem slow and complicated, making it difficult to integrate into a campaign timeline. Rapid tooling changes that. It’s a process built for speed and flexibility, allowing you to bring tangible ideas to life on an agency schedule. With the right rapid tooling services, you can extend your creative vision beyond the screen and deliver unforgettable physical products that your client’s audience will love.

Key Takeaways

Accelerate timelines and control costs: Rapid tooling is the ideal solution for producing high-quality physical products on a tight campaign schedule. It significantly reduces lead times and tooling expenses, making it perfect for limited runs, influencer kits, or prototypes.

Test and perfect your design with real parts: Use rapid tooling to create functional models from production-grade materials. This lets you validate everything from ergonomics to aesthetics before committing to a large order, ensuring the final product is flawless and client-approved.

Align your production strategy with project goals: The success of your project depends on choosing the right process. Define your production quantity upfront—rapid tooling is best for 50 to 5,000 units—and work with a partner who provides expert Design for Manufacturability (DFM) feedback to ensure a smooth path from concept to reality.

What is Rapid Tooling?

When you have a brilliant idea for a physical product—whether it’s for an immersive campaign, a high-end influencer kit, or a new merchandise line—the last thing you want is a long, drawn-out manufacturing process. You need to move fast. That’s where rapid tooling comes in. It’s a modern approach to creating the molds, dies, and other fixtures needed for manufacturing, but on a seriously accelerated timeline. Think weeks, not months. This speed allows you to get functional, high-quality parts in your hands quickly, so you can test your design, get client feedback, and launch your product without missing your deadline.

Get to Know the Basics

At its core, rapid tooling is a collection of techniques used to build production tools quickly and cost-effectively. Instead of committing to expensive, time-consuming traditional tooling right away, you can use rapid tooling to create parts for prototypes, market testing, or low-volume production runs. This process gives you a clear, real-world understanding of your product’s final look, feel, and function. It’s the perfect bridge between a digital design and a physical product, letting you validate your concept with tangible items before scaling up. For agencies, this means you can bring ambitious creative ideas to life without the traditional manufacturing bottlenecks.

Common Myths, Busted

Let’s clear the air on a common misconception: creating custom tooling is always slow and incredibly expensive. While that can be true for traditional, high-volume manufacturing, rapid tooling was developed specifically to solve that problem. The old-school process often involves high upfront costs and lead times that can stretch for months, which is a non-starter for most campaign timelines. Rapid tooling flips the script by using modern technology to create durable, precise tools much faster. It’s not about cutting corners; it’s about using a more efficient product development process to get you to the finish line sooner and with a much friendlier budget for smaller quantities.

A Look at the Core Technologies

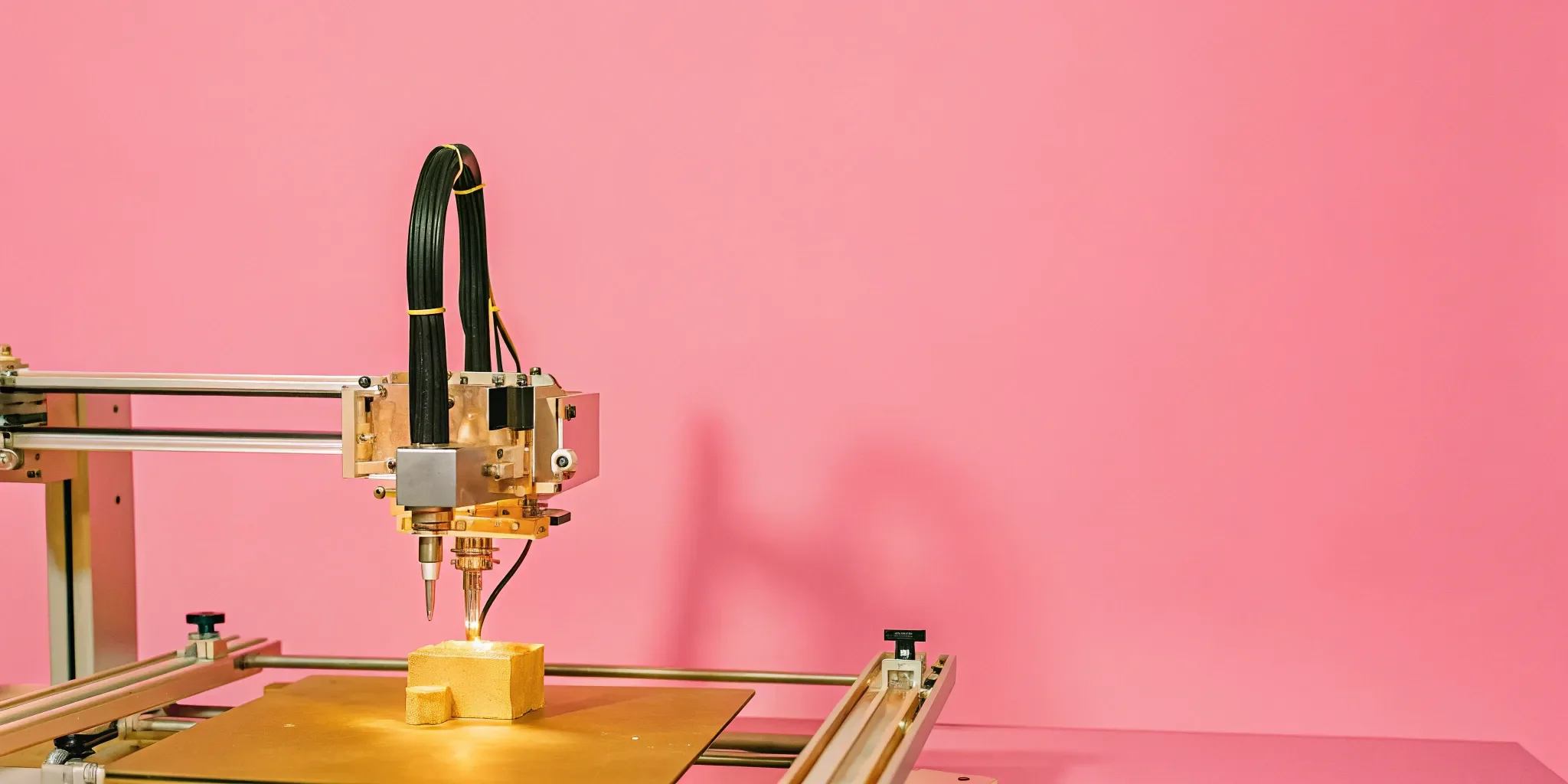

So, how do we actually make tools so quickly? It comes down to two key technologies: additive and subtractive manufacturing. Additive manufacturing, which you probably know as 3D printing, builds a tool layer by layer from a digital file. It’s incredibly versatile and perfect for creating complex geometries. Subtractive manufacturing, like CNC machining, does the opposite. It starts with a solid block of material and carves away until only the final tool remains. Both methods allow us to create things like custom injection mold inserts or fixtures with incredible precision, turning your digital design into a production-ready tool in a fraction of the time.

How the Rapid Tooling Process Works

Think of rapid tooling as the bridge between your digital design and a physical product you can hold in your hand. It’s a streamlined, structured process designed to create molds and produce parts in a fraction of the time it takes with traditional methods. This speed allows your team to get real-world feedback on a product's design, feel, and function without committing to the cost and time of full-scale production. It’s the perfect way to validate a concept, create a small batch for a marketing campaign, or produce high-quality prototypes that look and feel like the final product. The entire process is collaborative, turning your creative vision into a tangible, engineered reality.

From Your Design to a Finished Product

The journey from a 3D model to a finished part is surprisingly straightforward. It all starts with your design file, which our engineers review to ensure it’s optimized for manufacturing—a step that saves you time and headaches down the road. Once the design is locked, we create the mold, typically by machining aluminum or steel. After the mold is polished and assembled, we move to the most exciting part: the first test run. We inject plastic into the mold to create the first batch of sample parts. You get to see, touch, and test the physical product, ensuring it matches your vision perfectly before moving forward with a larger run.

Choose the Right Materials

Choosing the right material is about balancing aesthetics, function, and cost. Do you need something rigid and durable, or soft and flexible? Does it need to be crystal clear or a specific brand color? With rapid tooling, you have access to a huge library of production-grade plastics, so your prototypes can be made from the exact same material as your final product. We can guide you through the options, from common polymers like ABS and Polypropylene to specialized engineering-grade resins. This flexibility ensures your product not only looks great but also performs exactly as intended, whether it’s a sleek piece of tech or a custom-designed piece of packaging.

How We Ensure Top Quality

"Rapid" should never mean "low quality." We approach every rapid tooling project with the same meticulous attention to detail as a full production run. Quality starts with a solid design and precise engineering, but it doesn’t end there. We verify all raw materials and use advanced equipment to ensure every mold is machined to exact specifications. Once the first parts are produced, they go through a rigorous inspection process. We provide you with detailed reports and physical samples for approval, so you can be confident that every part meets your standards. This commitment to quality ensures the final product is something your client—and their customers—will love.

The Tech That Makes It Happen

The speed of rapid tooling is powered by a combination of advanced technologies. The workhorse of the process is CNC machining, which carves the mold out of a block of metal with incredible precision. For even faster turnarounds on simpler parts or prototypes, we can also leverage industrial 3D printing to create mold inserts. This hybrid approach allows for incredible flexibility. These technologies are most commonly used to create injection mold inserts, which are the core components that shape molten plastic into your final part. By combining these methods, we can quickly produce high-quality tools ready for low-volume manufacturing.

Rapid Tooling vs. Traditional Manufacturing

When you’re working on a tight campaign deadline, the last thing you need is a manufacturing process that moves at a snail's pace. Traditional manufacturing, with its long lead times and high costs, often isn’t a good fit for agency projects. This is where rapid tooling comes in. It’s a faster, more flexible approach designed to get physical products into your hands without the typical delays and massive upfront investment. Think of it as the bridge between a one-off prototype and a full-scale production run—perfect for when you need hundreds or thousands of high-quality items, and you need them now.

Launch Your Product Faster

The biggest advantage of rapid tooling is speed. Creating a traditional steel mold for injection molding can take months, a timeline that simply doesn’t work for most marketing campaigns or product launches. In contrast, rapid tooling helps turn product ideas into real objects in a matter of weeks, not months. By using materials like aluminum for the molds and streamlining the fabrication process, we can get your custom-branded products, influencer kits, or event giveaways ready in a fraction of the time. This means you can react quickly to market opportunities and get your client’s physical campaign assets delivered on schedule.

Save on Production Costs

For agency projects, budget is everything. You need to deliver high-impact results without the expense of a million-unit production run. Because rapid tooling molds are simpler and use more affordable materials, they can cost significantly less than molds built for mass production. In many cases, you can expect the tooling to be a fraction of the cost of traditional methods. This makes it financially feasible to produce limited-edition merchandise, sophisticated packaging, or custom-designed props that would otherwise be too expensive. It’s the ideal solution for creating a premium physical experience while keeping your project on budget.

Get More Freedom in Your Designs

Client feedback and creative pivots are part of agency life. With traditional tooling, making a design change late in the game is incredibly costly and time-consuming. Rapid tooling, however, is built for flexibility. The ability to easily modify designs is a huge benefit, allowing you to make adjustments based on feedback without derailing the entire project timeline or budget. Whether you need to tweak an enclosure for a new electronic component or refine the ergonomics of a branded product, this adaptable process lets you perfect the design before committing to a larger run, ensuring the final product is exactly right.

Scale Production as You Grow

Rapid tooling isn’t just for small test runs; it’s a powerful way to scale production intelligently. It’s the perfect middle ground when you need more than a handful of prototypes but aren’t ready to invest in tooling for hundreds of thousands of units. This method is ideal for producing a medium number of parts, often up to 100,000 pieces, depending on the material and design complexity. If your initial campaign is a hit and the client wants to expand the run, you’re already set up for it. This gives you a clear path to scale manufacturing as demand grows.

Why It Doesn't Compromise on Quality

It’s easy to assume that “rapid” and “low-cost” mean a drop in quality, but that’s not the case here. The parts produced with rapid tooling are just as precise and well-finished as those from a traditional mold. The key difference is the lifespan of the tool itself—an aluminum mold won’t last for a million cycles like a hardened steel one will, but it will produce thousands of flawless parts. We hold our rapid tools to the same high-quality standards as our full-production tools. For the volumes typical of agency projects, you get production-quality results without paying for a tool designed to last for decades.

How to Choose the Right Tooling Method

Picking the right tooling method might sound technical, but it’s one of the most important strategic decisions you’ll make for your product. It directly impacts your timeline, budget, and the final quality of what you deliver. Think of it like choosing between a 3D printer, a custom mold, or a full-scale factory assembly line—each is the right choice for a different kind of project. Your decision will come down to a few key questions: How many units do you need? How fast do you need them? And how likely is it that your design will change?

Understanding the difference between methods like soft tooling, hard tooling, and bridge tooling is the first step. Each one is designed for a specific phase of product development, from initial prototypes to a full market launch. Getting this choice right from the start saves you from costly mistakes and ensures your physical product lands with the impact your creative vision deserves. We’ll walk through the main options so you can feel confident in your production strategy.

Soft Tooling vs. Hard Tooling: What's the Difference?

Let’s break down the two main categories of tooling. Think of soft tooling as your go-to for prototypes or very small production runs. It often uses flexible materials like silicone to create molds that can produce a limited number of parts. This approach is fast and cost-effective, making it perfect for testing a design or creating a handful of high-fidelity models for a client presentation or an influencer kit.

Hard tooling, on the other hand, is built for the long haul. These tools are machined from durable metals like steel or aluminum and are designed for mass production. While the upfront investment is higher, a hard tool can produce hundreds of thousands of identical parts with incredible precision. The key difference is scale and longevity; soft tooling is for speed and small batches, while hard tooling is for volume and repeatability.

When to Use Bridge Tooling

What if you need more than a few prototypes but aren’t ready to commit to a massive production run? That’s where bridge tooling comes in. As the name suggests, it bridges the gap between prototyping and full-scale manufacturing. This method is a fast and affordable way to produce a few hundred to a few thousand parts, making it ideal for limited edition product drops, beta testing, or creating assets for a specific marketing campaign.

Bridge tooling gives you real, production-quality parts without the high cost and long lead times of traditional hard tooling. It allows you to validate your design with actual users, get to market faster, and work out any kinks before investing in tooling that’s meant to last for years. For agencies, it’s the perfect solution for delivering tangible products on a campaign timeline.

Compare Material Performance

When you’re creating a tool, the material it’s made from matters just as much as the part material. The two most common options for rapid tooling are aluminum and steel. While aluminum can be a good choice for simpler parts, it’s softer and wears down more quickly. For tools that need to be durable and precise, steel is often the better choice.

Some firms, for instance, exclusively use P20 steel for rapid tooling because it’s much stronger and lasts longer. Surprisingly, modern machining techniques make it just as fast to work with as aluminum, without a significant price difference. Prioritizing a robust material selection for the tool itself ensures every part comes out perfectly, from the first unit to the last, giving you a higher-quality result for your investment.

Match the Method to Your Production Needs

Ultimately, the best tooling method is the one that aligns with your specific goals. The key is to match the process to your required production volume and design flexibility. If you’re testing a new idea or only need a small batch of products for a launch event—say, between 50 and 5,000 units—then rapid tooling is almost always the right answer.

This approach is designed for speed and iteration. Because the tooling is less expensive and faster to create, you have the freedom to make design changes without derailing your budget or timeline. Before you commit to a method, get clear on your numbers. Knowing your target quantity will help you and your engineering partner understand your production volume and select the most efficient and cost-effective path to bring your product to life.

Solve Common Product Development Hurdles

Bringing a physical product to life for a campaign or brand launch comes with its own set of challenges. You’re often working against tight deadlines, strict budgets, and high client expectations. The last thing you need is a production snag that throws the entire project off course. This is where rapid tooling really shines—it’s designed to solve the exact hurdles that can derail creative projects, helping you move from concept to a tangible, client-approved product with more confidence and control.

By creating molds and parts quickly and cost-effectively, rapid tooling gives your team the flexibility to test, iterate, and perfect your product without the high stakes of traditional manufacturing. It’s about de-risking the development process so you can focus on what you do best: delivering an amazing creative experience.

Keep Your Project on Budget

One of the biggest concerns in any project is keeping costs in check. Committing to expensive, mass-production steel molds for a limited-run promotional item or a prototype can eat up your budget before you’ve even validated the design. Rapid tooling offers a more strategic approach. Because the molds are typically made from softer, more affordable materials like aluminum, this swift molding process can cost 60–80% less than traditional production tooling. This frees up your budget for other critical campaign elements and gives you the financial breathing room to experiment without the high financial risk. It’s a smarter way to manage resources, especially for one-off campaigns or influencer kits.

Shorten Your Timeline from Idea to Launch

Agency life moves fast, and production timelines need to keep up. When a campaign launch date is set in stone, you can’t afford to wait months for tooling. Rapid tooling is built for speed. Instead of the lengthy lead times associated with conventional manufacturing, you can have injection molding tools ready in as little as 10 days after the design is finalized. This incredible speed means you can get functional prototypes or small production runs in hand almost immediately. It allows your team to compress the development cycle, get client feedback faster, and hit your market deadlines without breaking a sweat. This acceleration is a game-changer for time-sensitive projects.

Test and Validate Your Design

Nothing is worse than discovering a design flaw after you’ve already committed to a full production run. Rapid tooling allows you to catch these issues early by creating high-fidelity prototypes that function just like the final product. You can use these parts for fit tests, functional assessments, and user feedback sessions. This early testing and adjustment phase is critical for refining ergonomics, ensuring mechanical parts work together seamlessly, and confirming the overall user experience. By validating your design with tangible, working models, you can make informed decisions and prevent costly mistakes down the line, ensuring the final product is flawless.

How to Test Your Materials

The look and feel of a product are everything, especially when it’s representing a brand. With rapid tooling, you aren’t limited to basic 3D-printed plastics. You can test your designs using the actual production-grade materials you intend to use for the final run. Whether it’s a specific grade of polycarbonate, a flexible TPE, or a durable ABS, you can create parts that accurately reflect the final product’s weight, texture, and performance. This allows you to evaluate everything from color matching to durability before committing to a large-scale order, ensuring the physical product perfectly aligns with your creative vision and your client’s brand standards.

Get the Most from Your Rapid Tooling Project

Rapid tooling is an incredible asset for bringing creative concepts into the physical world, but a successful project requires more than just a great idea. It’s about smart planning, strategic design, and clear communication with your production partner. When you’re working on a tight deadline for a campaign launch or an influencer kit, you need every step to be efficient and intentional. By focusing on a few key areas, you can ensure your project runs smoothly, stays on budget, and delivers a final product that perfectly captures your vision. Think of it as setting the foundation for a seamless transition from digital render to tangible result. Here’s how you can make sure your rapid tooling project is a home run from start to finish.

Optimize Your Design for Manufacturing

The most brilliant creative concept can hit a wall if it’s not designed for real-world production. This is where Design for Manufacturability (DFM) comes in. Rapid tooling is your first real chance to see how your product will look, feel, and function. It helps you catch potential issues—like a part that’s too thin to mold correctly or an assembly that’s too complex—before you’ve invested in a full production run. By working with an engineering-focused partner, you can refine your CAD models to be both beautiful and buildable. This collaborative step ensures your design intent is preserved while making the necessary tweaks for efficient, cost-effective manufacturing.

Plan Your Production Run

Rapid tooling shines in specific scenarios, so it’s important to align the process with your project goals. It’s the perfect solution for testing new ideas, creating limited-run products for a specific campaign, or producing bridge tooling while your mass-production molds are being made. Typically, rapid tooling is ideal for quantities between 50 and 5,000 units. This makes it a fantastic choice for high-value influencer kits, branded merchandise, or beta testing. With molds that can be ready in as little as 10 days, you can move incredibly fast. Knowing your target quantity helps your partner select the right materials and methods to get the job done right.

Implement Smart Quality Checks

"Rapid" should never mean a compromise on quality. Your physical product is a direct reflection of your client’s brand, so every detail matters. A reliable partner will have a rigorous quality control process, even for fast-turnaround projects. This includes verifying all raw materials and providing detailed inspection reports. You should expect to receive and approve first-off-the-tool sample parts before the full run begins. This critical checkpoint ensures that the color, texture, fit, and function match your exact specifications. Insisting on these quality assurance steps gives you the confidence that the final delivery will be flawless.

Minimize Common Production Risks

One of the biggest advantages of rapid tooling is its ability to reduce risk. Because the tooling itself can cost up to 80% less than traditional production molds, the upfront investment is significantly lower. This gives you the freedom to test a bold idea without committing a massive budget. If you discover a design flaw or get user feedback that requires a change, you can pivot quickly and affordably. This flexibility is invaluable for agency projects where timelines are tight and creative needs can evolve. Rapid tooling allows you to validate your concept with tangible, high-fidelity parts, ensuring your big idea is a proven success before you scale.

How to Choose the Right Partner

Finding a product development partner is a big deal, especially when you’re in the agency world. You’re not just hiring a vendor to execute a task; you’re bringing on a collaborator who will be responsible for turning your team’s creative vision into a physical reality. The right partner acts as an extension of your team, bringing the deep engineering and manufacturing know-how that makes ambitious ideas possible. They should understand the speed and creative demands of agency life—tight deadlines, shifting briefs, and the need for that "wow" factor—while providing the technical rigor needed to produce a flawless product.

When you’re vetting potential firms, it’s about finding a team that has the right blend of technical expertise, a commitment to quality, and a communication style that fits your workflow. Think of it as casting for a critical role in your project. You need someone who not only has the skills but also shares your commitment to delivering an incredible final result for your client. The best partnerships are built on trust and transparency, where your industrial design firm isn't just a supplier but a strategic guide helping you avoid pitfalls and find the smartest path from concept to production. This relationship is key to making sure the final product is not only delivered on time and on budget but also perfectly captures the brand’s story.

Assess Their Technical Capabilities

Rapid tooling is a specialized field, so you need a partner who truly lives and breathes it. Look beyond the sales pitch and dig into their actual capabilities. Do they have in-house expertise in both industrial design and mechanical engineering? Can they show you examples of projects similar to yours? A great partner will guide you through material selection and explain the trade-offs between different tooling processes. They should be able to look at your concept and immediately start thinking about how to make it manufacturable, durable, and beautiful. Ask about the specific technologies they use and how they handle complex designs. You want a team that can solve problems, not just follow instructions.

Look for Quality Standards and Certifications

"Rapid" should refer to the timeline, not the quality of the work. Your partner’s commitment to quality control is non-negotiable, especially when your agency’s reputation is on the line. Ask about their quality management system. Do they follow specific standards, like ISO 9001? A reliable firm will have a clear process for inspecting raw materials and finished parts. They should be able to provide material certifications and inspection reports to guarantee that what you designed is what you get. The best partners promise the same high quality for rapid tools as they do for production tools, ensuring your final product is something you’re proud to put in front of a client.

Evaluate the Cost and Potential ROI

Agency projects live and die by the budget, so cost is always a key factor. The good news is that rapid tooling is designed to be cost-effective, often costing significantly less than traditional production tooling. But a low price tag isn't the whole story. The real return on investment comes from speed and flexibility. A great partner helps you get a physical product to market or into a campaign faster, which can be priceless. When you get quotes, make sure they are transparent and all-inclusive. A trustworthy partner will provide a detailed breakdown and help you understand the cost benefits without any hidden fees, ensuring your project stays on budget from start to finish.

Prioritize Clear Communication and Support

This might be the most important factor of all. The best engineering firm in the world is useless to you if they don’t communicate well. Your partner should feel like a true collaborator—responsive, proactive, and easy to work with. Look for a team that offers comprehensive support, including Design for Manufacturing (DFM) feedback. This is where they analyze your design and suggest improvements to make it more efficient and less expensive to produce, all while preserving your creative intent. A dedicated project manager who understands your goals and provides regular updates is a must. You need a partner who makes the entire process feel seamless, not stressful.

Related Articles

Frequently Asked Questions

How fast is "rapid" tooling, really? This is the most important question, and the answer is: much faster than you think. While traditional manufacturing can take months to create a production tool, a rapid tool can be ready in a matter of weeks, sometimes as little as 10-15 days. This means you can go from a finalized digital design to holding a physical, molded part in your hands in a timeframe that actually works for a campaign launch or event.

Will the quality of my product suffer if we use a "rapid" process? Not at all. This is a common misconception, but the "rapid" part refers to the speed of creating the tool, not the quality of the parts it produces. The parts made from rapid tooling are production-grade and can be just as precise and beautifully finished as those from a traditional mold. The main difference is the tool's lifespan; it’s built for thousands of parts, not millions. For the quantities needed for most agency projects, the quality is identical.

What's the sweet spot for quantity? Is this for 10 items or 10,000? Rapid tooling is the perfect solution for when you need more than a handful of prototypes but aren't ready for a massive production run. The ideal range is typically anywhere from 50 to 5,000 units. This makes it a fantastic choice for projects like high-end influencer kits, limited-edition merchandise, beta testing units, or custom assets for a marketing activation where you need a few hundred or a couple thousand perfect pieces.

What if we need to change the design after seeing the first parts? This is actually one of the biggest strengths of the rapid tooling process. Because the initial tooling investment is much lower than with traditional methods, making adjustments is far less painful for your timeline and budget. This flexibility allows you to test the first samples, gather client feedback, and make necessary tweaks before committing to the full production run. It’s a process built to accommodate the iterative nature of creative work.

What do I need to have ready before I can start a rapid tooling project? To get started, the most important thing you need is a 3D CAD file of your product design. This is the digital blueprint our engineers will use to create the tool. Don't worry if it's not perfect; a good partner will review your design for manufacturability and suggest refinements to ensure the final product is both beautiful and buildable. Having a clear idea of your desired quantity and material will also help get the process moving quickly.