What Does a Mechanical Design Consultancy Do?

Your agency is always looking for a competitive edge—a way to offer clients something truly innovative that other firms can't. What if you could confidently pitch and execute complex physical products as part of your campaigns? By having the right technical partner, you can. A mechanical design consultancy acts as your secret weapon, giving you the in-house capability to develop everything from smart devices to interactive retail displays without the overhead of a full engineering team. This partnership allows you to expand your creative services, take on more ambitious projects, and deliver unforgettable, tangible brand experiences that set you far apart from the competition.

Key Takeaways

- Translate Creative Vision into a Buildable Product: A mechanical design consultancy handles the complex engineering needed to make your physical product idea a reality. They figure out the internal mechanics, materials, and structure to ensure the final product is functional, durable, and ready for manufacturing.

- Vet for Technical Depth and a Collaborative Spirit: The right partner is more than a portfolio; they're an extension of your team. Confirm they have deep engineering expertise (like DFM) and a working style that fits your agency's pace, ensuring a smooth process from creative brief to final deliverable.

- Demand a Unified Design and Engineering Process: The best results come when industrial design and mechanical engineering happen in parallel, not in sequence. This unified approach prevents costly redesigns, speeds up timelines, and ensures the product you present to your client is both beautiful and technically sound.

What is a Mechanical Design Consultancy?

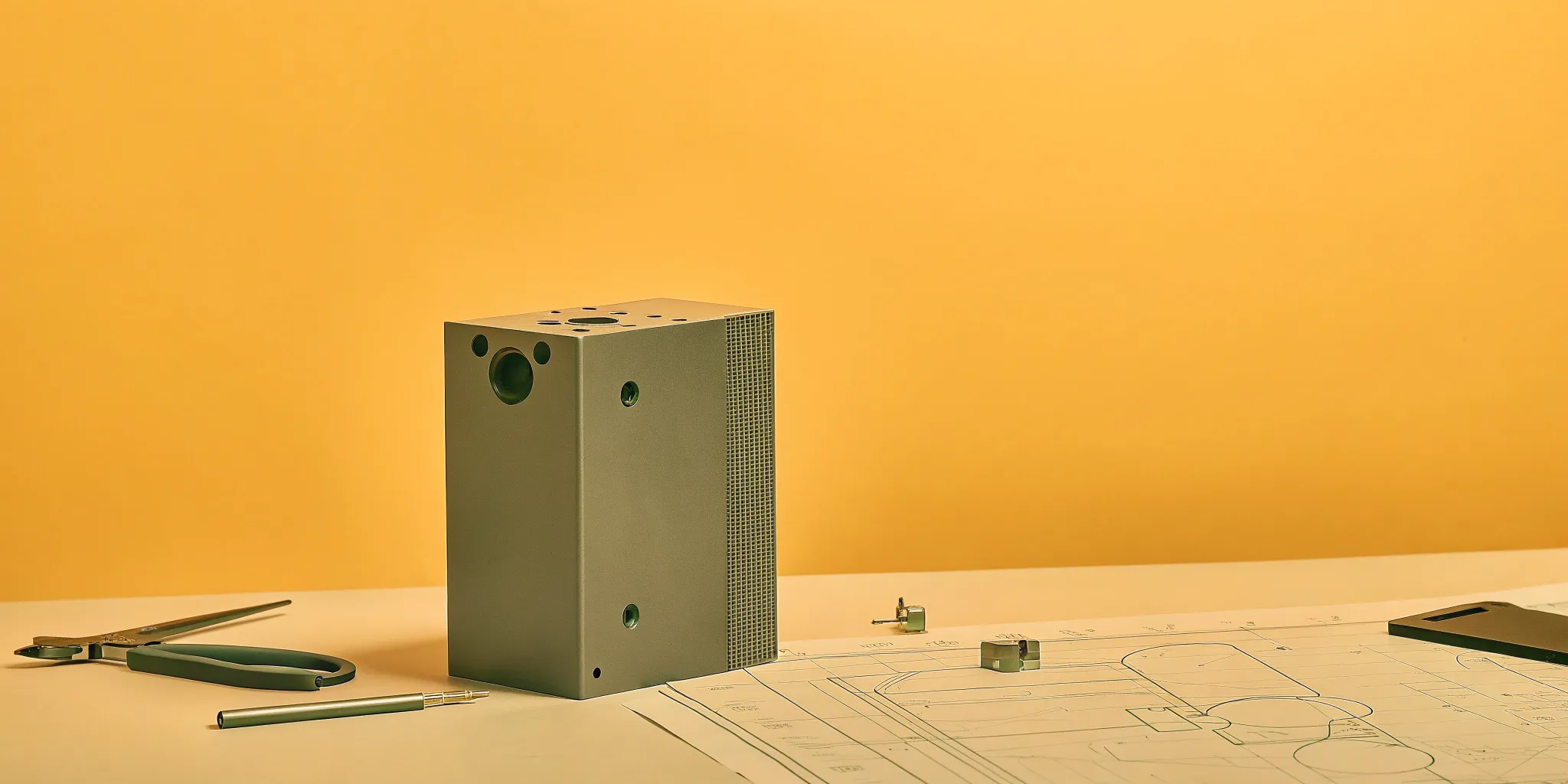

Think of a mechanical design consultancy as the expert engineering team you bring in to turn a brilliant product idea into a tangible, functional reality. When your agency has a concept for a physical product—whether it's a piece of branded tech, a custom influencer kit, or an interactive retail display—a consultancy handles all the technical heavy lifting. They are the bridge between your creative vision and a final, manufacturable product that works exactly as it should.

These firms are staffed with mechanical engineers and designers who live and breathe the physics of how things work. They figure out the internal mechanisms, the materials, the structure, and how all the pieces will fit together perfectly. Essentially, they answer the critical question: "How do we actually build this?" By partnering with a consultancy, you’re not just getting a designer; you’re getting a strategic engineering partner who ensures your creative concept is built on a solid, reliable foundation. They transform ambitious ideas from a sketch on a whiteboard into a high-performance product ready for the real world.

Core Design and Engineering Services

At its heart, a mechanical design consultancy provides the core engineering needed to develop a product from the ground up. This starts with taking your initial concept or creative brief and translating it into a detailed mechanical design. Using advanced 3D computer-aided design (CAD) software, engineers map out every single component, defining its shape, size, and material. They design the internal architecture, ensuring all parts work together seamlessly.

This process isn't just about drawing pretty pictures; it's about solving complex functional puzzles. Whether they’re creating a completely new product or improving an existing one, their job is to make sure the final item is functional, durable, and reliable. They are the architects and builders of your product's inner workings, providing the mechanical engineering expertise to make sure it performs flawlessly.

Prototyping and Testing Capabilities

Before you commit to producing thousands of units, you need to know the product actually works. This is where prototyping and testing come in. A mechanical design consultancy creates functional prototypes—early versions of your product that you can hold, use, and test. This step is absolutely critical for catching design flaws, refining ergonomics, and validating that the product meets your agency’s and your client’s expectations. It’s the best way to move from a digital model to a physical object.

These prototypes aren't just for show; they undergo rigorous testing to identify potential weaknesses. Engineers will simulate real-world conditions to see how the product holds up. This process of iterative prototyping helps solve performance issues before they become costly manufacturing problems, ensuring the final product is polished, reliable, and ready for launch.

Manufacturing and DFM Support

Having a beautiful, functional prototype is great, but it’s useless if it can’t be manufactured efficiently and at a reasonable cost. This is why Design for Manufacturing (DFM) is such a crucial service. DFM is the practice of designing products in a way that makes them easy and economical to produce. A good mechanical design partner thinks about the manufacturing process from the very beginning, making smart choices that save time and money down the line.

This involves selecting cost-effective materials, simplifying complex parts, and designing for straightforward assembly. By optimizing the design for production, they help you avoid common manufacturing pitfalls that can cause delays and budget overruns. This practical, forward-thinking approach ensures a smooth handoff to the factory and helps your project stay on track.

Thermal and Structural Analysis

For many products, especially electronics, managing heat and physical stress is non-negotiable. This is where thermal and structural analysis comes into play. Using sophisticated simulation software, engineers can predict how a product will behave under different conditions before a single physical part is made. Thermal analysis assesses how heat generated by components (like batteries or processors) will dissipate, preventing the device from overheating and failing.

Similarly, structural analysis evaluates the product's strength and durability. Engineers can simulate drops, impacts, and daily wear and tear to ensure the design is robust enough to withstand real-world use. This digital testing is key to building a safe, reliable product and preventing embarrassing failures that could damage your client’s brand reputation. It’s the behind-the-scenes work that guarantees quality.

Which Industries Rely on Mechanical Design?

Mechanical design is the invisible architecture behind almost every physical product you can think of. It’s not just about gears and heavy machinery; it’s the discipline that ensures a product works correctly, feels right in your hands, and can actually be built. For creative agencies, this is a huge deal. Whether you’re developing a sleek piece of branded tech, an interactive mailer, or a custom retail display, the principles of mechanical design are what turn a great idea into a functional reality. It’s the bridge between a beautiful concept on a screen and a tangible object that can be unboxed, used, and loved.

Understanding where this expertise is applied helps you see the possibilities for your own projects. The same engineering rigor that goes into designing a medical device can be applied to creating a durable, high-end consumer product for your client. It’s about borrowing best practices from fields where there is zero room for error. From consumer electronics that need to be both beautiful and robust to industrial equipment where function is everything, mechanical design provides the foundation. Let’s look at a few key industries where this work is absolutely critical and see what lessons we can pull for brand projects.

Consumer Products and Electronics

This is where form and function have to be perfectly balanced. Think about the products your clients want to create: smart speakers, wearable fitness trackers, wireless headphones, or even high-end kitchen gadgets. A mechanical design team is responsible for making sure all the internal components fit perfectly within a sleek enclosure. They figure out how to make it durable enough for daily use, easy to assemble in a factory, and satisfying to hold and interact with. This process involves everything from material selection to ensuring the final product meets both functional and aesthetic requirements. It’s the detailed engineering that makes a product feel premium and reliable, not just a hollow prototype.

Medical and Healthcare Devices

While you might not be pitching a surgical instrument, the medical industry is a masterclass in precision, safety, and user-focused design. Mechanical engineers in this space create everything from diagnostic tools to wearable health monitors. They work under incredibly stringent regulatory standards, which means every single component must be reliable and safe. The principles learned here—like ergonomics for ease of use and material science for durability and biocompatibility—are directly applicable to creating high-quality consumer products. This level of rigor ensures that a product isn’t just clever, but also trustworthy and built to last.

Automotive and Aerospace

In industries where performance and safety are non-negotiable, mechanical design is paramount. Engineers in the automotive and aerospace sectors design components that have to withstand extreme temperatures, vibrations, and stress while performing flawlessly every time. The precision and reliability demanded by these fields set a high bar for engineering excellence. For agencies, partnering with a firm that has this kind of expertise means your product—whether it’s a rugged piece of outdoor gear or a premium automotive accessory for a client—is built with an understanding of what it takes to create something truly robust and dependable. It’s about applying that same performance-driven mindset to any physical product.

Industrial Machinery and Equipment

Designing industrial equipment is the ultimate test of function. These machines are built for performance, efficiency, and longevity in demanding environments. Mechanical designers in this field are experts at solving complex challenges in the most direct and cost-effective way possible. This expertise is incredibly valuable even if you’re not building a factory robot. A design partner with industrial experience understands the realities of manufacturing inside and out. They know how to design for assembly (DFA), select the right materials for the job, and ensure a concept is not just creative but also practical and affordable to produce at scale.

How to Choose the Right Mechanical Design Partner

Finding the right mechanical design partner is a lot like casting the lead in a film. You need someone with the right skills, a proven track record, and the ability to collaborate seamlessly with your creative team. The success of your physical product—whether it’s a piece of high-tech merch or custom packaging for an influencer kit—hinges on this choice. A great partner doesn’t just execute your vision; they enhance it with engineering expertise, ensuring the final product is not only beautiful but also functional, durable, and ready for production.

When you’re vetting potential firms, you’re looking for more than just a vendor. You’re looking for a true collaborator who can speak both the language of creative briefs and the language of technical specifications. They should feel like an extension of your own team, ready to solve problems and bring your most ambitious ideas to life. Let’s walk through the key areas to focus on so you can find a partner who will make your project a success.

Evaluate Their Technical Expertise

Before you get swept away by a slick portfolio, it’s important to confirm your potential partner has the technical depth to back it up. Look for a team that offers a wide range of mechanical engineering services and can speak confidently about the entire product development lifecycle. Ask them about their experience with Design for Manufacturability (DFM), material selection, and thermal analysis. Do they have in-house electrical engineers if your project involves electronics?

A great partner can explain complex engineering concepts in a way that makes sense to non-engineers. They should be able to anticipate potential production hurdles from the very first sketch and design solutions to avoid them. This level of foresight is what separates a good design firm from a great one, saving you time, money, and stress down the line.

Review Their Portfolio and Experience

A portfolio is your best window into a firm’s capabilities and style. As you review their past work, look for projects that share similarities with yours, whether in complexity, materials, or function. A firm with a deep bench of skilled engineers and designers will have a diverse portfolio that showcases their problem-solving abilities across different industries. Don’t just look at the final photos; ask for the story behind the product.

Inquire about the specific challenges they faced and how they overcame them. For example, how did they handle a tight deadline or a difficult manufacturing constraint? A team with decades of combined experience in mechanical product design will have plenty of stories to tell. This gives you a much clearer picture of their process and how they perform under pressure, which is essential for the fast-paced agency world.

Understand Their Collaboration Style

For an agency, a partner’s collaboration style is just as important as their technical skill. You need a team that can integrate smoothly into your creative process. Ask them how they typically work with clients. Do they have a structured process for feedback and approvals? How do they handle communication and project updates? Look for a firm that values transparency and is comfortable working in an iterative, creative environment.

The best partners act as a true extension of your team. They understand that creative direction can evolve, and they’re agile enough to adapt without derailing the project. A firm that outlines a clear process for mechanical development from the start shows they respect your time and goals. This alignment ensures that the creative vision and engineering execution remain in sync from kickoff to delivery.

Check Their Project Management Process

A great idea can fall apart without solid project management. Before signing on, get a clear understanding of how the firm manages timelines, budgets, and deliverables. Who will be your main point of contact? How often can you expect updates? A professional firm will have a clear, transparent process for tracking progress and managing resources, ensuring there are no surprises along the way.

Ask them how they handle scope changes and unexpected mechanical challenges. A seasoned partner will have contingency plans in place and will communicate proactively when issues arise. This level of organization and foresight is critical for keeping your project on schedule and within budget. Ultimately, you want a partner who is as committed to the project’s business goals as they are to its creative and technical excellence.

Understanding Costs and Project Outcomes

Bringing a physical product to life involves a different set of variables than a digital campaign, but the goal is the same: deliver an amazing experience on time and on budget. When you partner with an industrial design and engineering firm, understanding how costs are determined and how success is measured is key to a smooth collaboration. It’s not about finding the cheapest option; it’s about finding the best value and ensuring your creative vision is executed flawlessly. Let’s break down what you can expect.

What Influences Pricing

The cost of a project isn’t just a number pulled out of a hat. It’s a reflection of the time, expertise, and resources required to turn your idea into a tangible product. Key factors include the project's complexity—a simple branded item will cost less than a custom electronic device with moving parts. The required level of engineering and the experience of the design team also play a big role. A seasoned firm can often solve problems faster and avoid costly mistakes down the line. We always aim to work within your client's budget, so an open conversation about financial parameters helps us propose the most effective path forward and build a positive working relationship from day one.

How to Measure Success

For agencies, success is ultimately about client satisfaction and campaign impact. In product development, we track specific metrics to make sure we’re hitting those goals. Beyond the obvious—like delivering on schedule and within budget—we measure things like time-to-market to ensure your product is ready for a critical launch date. We also focus on manufacturability, which means the final design is efficient and cost-effective to produce at scale. By tracking KPIs throughout the process, we can get a clear picture of how well we’re meeting your needs, spot potential issues early, and ensure the final product delivers measurable value for your brand campaign.

Overcoming Common Challenges

The biggest hurdles in product development often pop up early on. One of the most common is an incomplete or vague brief. Without a clear definition of the product’s goals, features, and constraints, you risk scope creep and delays. Another challenge is overlooking design for manufacturability (DFM). A concept might look incredible on screen, but if it’s impossible or wildly expensive to produce, it’s not a viable solution. A great partner helps you handle these issues by asking the right questions upfront and keeping production realities in mind from the very first sketch. This is why it's important to select your design consultants based on their quality and reputation, not just their price tag.

Setting Expectations for ROI and Timelines

Clear expectations are the foundation of any successful project. From the start, we work with you to establish a realistic timeline that accounts for design iterations, prototyping, testing, and manufacturing lead times. Transparency is everything. We believe price fairness is crucial for building trust, so we provide detailed proposals that outline every phase of the project. The return on investment (ROI) for a physical product can be huge—creating brand loyalty, generating buzz, and providing a tangible connection with an audience. Our job is to map out the clearest, most efficient path to achieving that ROI, keeping you informed and confident at every step.

Our Approach as Your Mechanical Design Partner

Choosing a mechanical design partner is about more than just finding someone with technical skills; it’s about finding a team that gets your creative vision and can translate it into a physical, functional product without a hitch. For agencies, this partnership is even more critical. You need a team that can move at the speed of your campaigns and deliver tangible results that impress your clients. We’ve built our entire process around being that silent, expert partner who makes your most ambitious physical product ideas a reality. We handle the complex engineering so you can focus on the big picture.

Our approach is designed to be seamless, transparent, and collaborative. We don’t just take a brief and disappear. We work as an extension of your creative team, providing the technical foundation that ensures your product, package, or experiential asset is not only beautiful but also robust, manufacturable, and ready for the real world. Think of us as your in-house product development arm, ready to jump in and bring your concepts to life with precision and speed.

Integrated Design and Engineering

The best products are born when design and engineering work together from day one. Our process is built on this principle of integrated product development. We don’t separate form from function; we develop them in parallel. This means our industrial designers are constantly talking to our mechanical engineers, ensuring that every aesthetic choice is grounded in structural reality and every mechanical component supports the overall design intent. This prevents those classic, project-killing scenarios where a beautiful concept turns out to be impossible or wildly expensive to actually build. By blending creative design with rigorous engineering from the start, we create products that are visually compelling, technically sound, and optimized for manufacturing.

A Collaboration Model Built for Agencies

We know that agencies operate on tight timelines and high expectations. Our collaboration model is specifically designed to fit right into your workflow. We act as your behind-the-scenes product development team, whether you need us white-labeled or as a named partner. You bring the creative vision and client insight; we bring the deep technical expertise to execute it flawlessly. We’re fluent in the language of creative briefs and campaign goals, and we’re structured to be nimble and responsive. Our goal is to make the entire process—from initial sketch to final prototype—feel effortless for you, ensuring a smooth transition from a creative idea to a tangible product you can proudly present to your client.

Our Advantage: Speed and Technical Depth

In the agency world, speed is everything. But speed without precision is useless. Our advantage lies in our ability to combine rapid execution with deep engineering expertise. As a focused, hands-on firm, we cut out the layers of bureaucracy that slow down larger consultancies. Every project is overseen directly by our founder, Jackson Hedden, ensuring that critical decisions are made quickly and intelligently. This lean structure allows us to tackle complex mechanical challenges and iterate on designs without missing your deadlines. We use our technical depth to find creative, cost-effective solutions that keep your project moving forward, delivering high-quality, engineered outcomes on a campaign timeline.

End-to-End Product Development

We guide your idea through every stage of the product development lifecycle, from a simple concept to a production-ready design. Our process is structured yet flexible, covering everything from initial requirements analysis and industrial design to detailed mechanical engineering and CAD modeling. We build and test prototypes to validate the design, ensuring everything works exactly as it should. Finally, we deliver a complete package—including master assembly drawings and a Bill of Materials (BOM)—that provides a clear roadmap for manufacturing. This comprehensive approach means you can hand us a concept with confidence, knowing we’ll manage all the technical details needed to bring it to life.

Related Articles

- Product Design for Manufacturing: A Practical Guide — Jackson Hedden

- Product Development Services: A Complete Guide — Jackson Hedden

- Product Design Success Stories & Client Reviews | Jackson Hedden Inc

Frequently Asked Questions

My agency has a great idea for a product, but it's just a concept. Is that enough to start a project? Absolutely. A strong concept is the perfect starting point. Our job is to partner with you to translate that creative vision into a concrete, technical plan. We begin by discussing your goals, target audience, and desired features. From there, our engineers and designers can flesh out the details, turning your initial idea into a fully realized design ready for prototyping and production. You bring the "what" and the "why," and we'll handle the "how."

What's the real difference between industrial design and mechanical engineering? Think of it this way: industrial design focuses on the user's experience—how the product looks, feels, and functions from the outside. It’s about aesthetics, ergonomics, and the overall user interaction. Mechanical engineering is what makes it all work on the inside. It’s the science of designing the internal structure, mechanisms, and components to ensure the product is durable, reliable, and can actually be manufactured. You need both to create a product that is beautiful on the outside and brilliant on the inside.

Why can't we just take our design directly to a factory? Factories are experts at mass production, but they aren't set up to solve design problems. A concept that looks great on screen might be incredibly difficult or expensive to build in reality. A mechanical design partner ensures your product is optimized for manufacturing (DFM) before it gets to the factory. We solve potential issues with materials, assembly, and durability early on, which prevents costly errors and delays down the line and ensures a much smoother production run.

How involved will our team need to be in the process? We see this as a true partnership. Your team is the expert on the brand vision and campaign goals, and we rely on that insight. We'll need you most at key stages, like initial brainstorming, design reviews, and prototype feedback sessions. Our goal is to handle all the technical complexities so you can focus on creative direction. We manage the day-to-day engineering work and provide clear, consistent updates, making the process feel collaborative, not burdensome.

What kind of final files or deliverables do we receive? At the end of our process, you get a complete technical package that is ready to be handed off to a manufacturer for production. This includes the final 3D CAD (computer-aided design) files, which are the digital blueprints for every part. You'll also receive a detailed Bill of Materials (BOM) that lists every single component needed, and master assembly drawings that show the factory exactly how to put it all together. It’s everything a manufacturer needs to build your product accurately and consistently.